MultiJet Printing (MJP) Technology is an advanced 3D printing method that creates high-resolution, multi-material objects with impressive precision. Known for producing smooth finishes and intricate details, MJP is widely adopted for applications requiring accuracy and complexity, such as in healthcare, automotive, and electronics. The technology works by depositing layers of photopolymer resin, allowing for rapid, precise part creation. Its speed, versatility, and ability to handle complex designs make MJP a game-changer in modern manufacturing across diverse industries.

Industry 1 – Healthcare

MultiJet Printing (MJP) Technology has revolutionized the healthcare industry by enabling precise, custom solutions that enhance patient care and medical research.

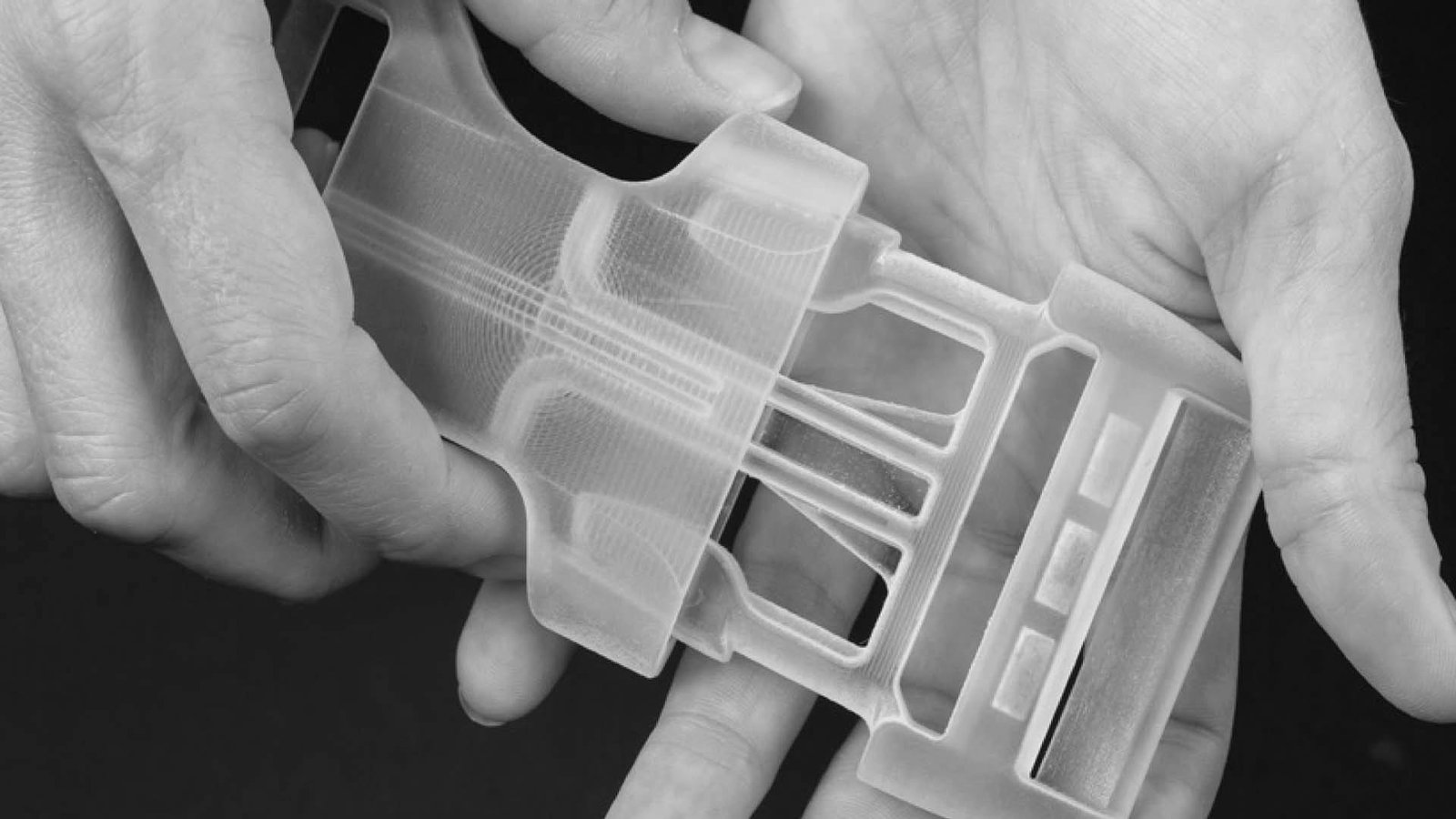

Custom Prosthetics and Implants

MJP allows for the creation of custom prosthetics and implants tailored to fit individual patients’ anatomies. These customizations improve patient comfort, fit, and function, making healthcare more personalized and effective.

Surgical Planning Models and Medical Equipment

MJP is used to create highly accurate anatomical models that aid surgeons in pre-surgical planning, reducing risks during complex procedures. Additionally, MJP enables rapid prototyping of specialized medical tools, facilitating innovation.

Benefits of MultiJet Printing for Healthcare

The technology’s high precision, customization capability, and fast turnaround are particularly valuable in healthcare, where tailored solutions and efficiency can significantly impact patient outcomes.

Industry 2 – Automotive

MultiJet Printing (MJP) Technology is accelerating innovation in the automotive industry by enabling faster, more flexible production of complex components and prototypes.

Rapid Prototyping and Functional Testing

MJP supports automotive manufacturers in rapidly developing prototypes for new parts, allowing for quick adjustments and functional testing. This speed up the design process and reduces time-to-market for new vehicle models.

Production of Complex and Lightweight Parts

MJP enables the production of intricate, lightweight components essential for modern vehicles. These parts help reduce overall vehicle weight, enhancing fuel efficiency without sacrificing strength or durability.

Advantages of MultiJet Printing in Automotive Production

For the automotive sector, MJP offers cost-effective, precision-driven production, enabling manufacturers to innovate faster while maintaining high-quality standards. The flexibility of MJP supports design creativity and efficiency, making it ideal for developing the next generation of vehicles.

Industry 3 – Electronics

MultiJet Printing (MJP) Technology is transforming the electronics industry by enabling the precise fabrication of small, complex components essential for modern devices.

Printed Circuit Boards (PCBs) and Micro-Components

MJP is instrumental in producing high-precision PCBs and intricate micro-components required in today’s compact and high-performance electronics. This precision ensures that components fit perfectly, maintaining product reliability and performance.

Custom Housing and Enclosures for Electronics

With MJP, manufacturers can create customized housings and enclosures that protect sensitive electronic parts. These enclosures are designed to exact specifications, providing durability and safeguarding internal components.

MultiJet Printing’s Value in Electronics Manufacturing

The technology’s ability to produce intricate designs at a micro-level, along with its flexibility, enables electronics companies to meet the growing demand for miniaturization and functional customization in devices, from consumer electronics to industrial applications.

Industry 4 – Consumer Goods

MultiJet Printing (MJP) Technology is reshaping the consumer goods sector by enabling rapid customization and enhancing product design flexibility.

Customization in Product Design

MJP allows brands to offer personalized products, from jewelry to home decor, tailored to individual preferences. This level of customization is increasingly popular among consumers seeking unique, one-of-a-kind items.

Rapid Iterations and Product Testing

With MJP, companies can quickly develop and test multiple versions of a product design. This agility allows brands to respond swiftly to market trends and consumer feedback, ensuring products meet customer expectations.

Benefits for the Consumer Goods Industry

MJP’s fast production, detail accuracy, and customization capabilities allow consumer goods manufacturers to bring high-quality, innovative products to market more efficiently, enhancing brand appeal and customer satisfaction.

Industry 5 – Education and Research

MultiJet Printing (MJP) Technology is advancing education and research by providing hands-on learning tools and supporting innovative research projects.

Hands-On Learning and Research Prototyping

Educational institutions utilize MJP to give students practical experience with prototyping and design. This hands-on exposure is invaluable in fields such as engineering, architecture, and medicine, where students can create models and functional prototypes.

Research in Material Science and Engineering

MJP enables researchers to experiment with new materials and complex geometries, pushing the boundaries in material science and engineering. It supports research in fields like biomechanics, nanotechnology, and structural testing.

How MultiJet Printing Benefits Education

The precision, flexibility, and rapid prototyping capabilities of MJP encourage creativity and innovation in education, making it a powerful tool for both teaching and research. Students and researchers benefit from real-world applications and the opportunity to explore complex ideas in tangible form.

Conclusion

MultiJet Printing Technology is driving significant advancements across healthcare, automotive, electronics, consumer goods, and education by enabling high precision, customization, and efficiency. As industries continue to innovate, MJP stands out as a vital tool, empowering businesses and institutions to meet modern demands with agility and accuracy.