Direct Metal Laser Sintering (DMLS) revolutionizes manufacturing by enabling precise metal part production. However, challenges like accuracy and speed persist. This blog explores how AI and Machine Learning enhance DMLS printing, improve efficiency, and drive innovation in various industries, particularly in India.

Overview of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are transforming various industries by enabling systems to learn from data, make decisions, and improve over time. In the context of DMLS printing, these technologies offer significant enhancements, addressing traditional challenges and pushing the boundaries of what’s possible.

How AI is Integrated into DMLS Printing

AI integration in DMLS involves using advanced algorithms to optimize the printing process. This includes designing more efficient build paths, predicting potential issues, and adjusting parameters in real-time. Machine Learning models analyze vast amounts of data from previous prints to improve future outcomes, ensuring higher quality and consistency.

Benefits of Using AI in DMLS

Improved Accuracy

AI algorithms enhance the precision of DMLS printing by predicting and correcting deviations during the printing process. This results in parts with finer details and tighter tolerances, meeting stringent industry standards.

Enhanced Speed

Machine Learning optimizes the printing process by dynamically adjusting parameters such as laser speed and power. This leads to faster print times without compromising quality, significantly boosting productivity.

Cost Efficiency

AI-driven process optimization reduces material waste and energy consumption. By minimizing errors and reprints, manufacturers can lower operational costs, making DMLS printing more economically viable for a wide range of applications.

AI in Design Customization

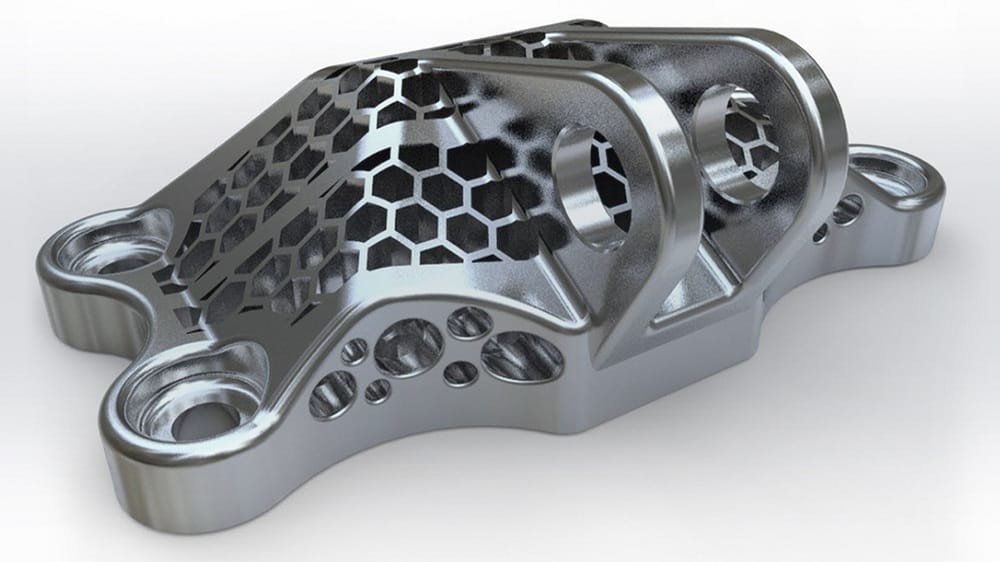

AI technologies are revolutionizing design customization in DMLS printing. Advanced algorithms enable the creation of complex geometries that were previously impossible or too costly to produce. AI-driven design tools can automatically generate optimized structures, ensuring strength and functionality while minimizing material usage. This customization capability is particularly valuable in industries like aerospace and medical, where tailored solutions are crucial.

Machine Learning for Process Optimization

Machine Learning plays a pivotal role in optimizing the DMLS printing process. By analyzing vast datasets from past prints, ML algorithms identify patterns and correlations that human operators might miss. These insights lead to the continuous improvement of process parameters, such as laser power, scan speed, and layer thickness. The result is a more efficient printing process that consistently produces high-quality parts with fewer defects.

Real-time Monitoring and Adjustment

One of the most significant advantages of integrating AI in DMLS printing is the ability to monitor the process in real-time. Sensors and cameras collect data throughout the printing cycle, which is then analyzed by AI systems. Any anomalies or deviations from the expected behaviour are instantly detected, allowing for immediate adjustments. This real-time monitoring ensures that potential issues are addressed before they escalate, resulting in higher yield and reduced downtime.

Quality Control and Defect Detection

Automated Quality Control with AI

- AI-powered systems automate inspection processes.

- Advanced image recognition and data analysis for layer-by-layer inspection.

- Detects minute defects that manual inspection might miss.

- Ensures a higher standard of quality.

Machine Learning Algorithms for Defect Detection

- Analyzes large datasets to recognize patterns indicating potential issues.

- Identifies defects such as porosity, surface roughness, and dimensional inaccuracies.

- Real-time application allows for immediate corrective actions.

- Prevents costly reprints and material wastage.

Reducing Waste and Improving Yield

- Optimizes the printing process for higher accuracy and efficiency.

- Minimizes material waste due to fewer defects.

- Enhances defect detection capabilities, leading to fewer rejected parts.

- Increases overall yield, particularly beneficial for high-cost industries.

Conclusion

AI and Machine Learning are revolutionizing DMLS printing by enhancing accuracy, speed, and cost-efficiency. These technologies optimize design, monitor processes in real-time, and improve quality control, ensuring high standards and reducing waste. As AI continues to evolve, its integration in DMLS printing will drive further innovations, making manufacturing more efficient and adaptable. Embracing these advancements is crucial for staying competitive in industries where precision and customization are key.

Explore how Tesseract’s cutting-edge AI-driven DMLS solutions can revolutionize your manufacturing process. Contact us today to learn more and transform your production capabilities!