Optimizing 3D models is crucial for achieving faster print times and superior results. By refining your design and adjusting key factors like geometry, wall thickness, and support structures, you can significantly reduce printing time and material usage. Whether you’re a hobbyist or a professional in India, optimizing your models ensures that you get the most out of your 3D printer, leading to cost-effective, high-quality prints with fewer errors and smoother finishes.

Why Model Optimization is Important in 3D Printing

Optimizing 3D models is essential for achieving efficient, high-quality prints. Faster printing not only saves time but also reduces energy consumption and operational costs, making it more cost-effective for users. In India, where affordability and resource efficiency are key, model optimization ensures that printers perform at their best. By minimizing material wastage and improving print accuracy, optimization reduces the risk of failed prints, resulting in better output and a smoother, more reliable 3D printing experience.

Key Factors to Optimize 3D Models for Better Results

To achieve faster printing and higher-quality results, optimizing your 3D models is essential. Here are the key factors to consider:

Simplifying Geometry for Faster Prints

Simpler models with fewer complex details print faster. Reducing polygon count and eliminating unnecessary details can significantly speed up the process while maintaining structural integrity.

Adjusting Wall Thickness and Layer Height

Optimal wall thickness and layer height are crucial. Thicker walls increase strength but slow down printing. For faster results, use thinner walls and increase layer height, balancing print speed and durability.

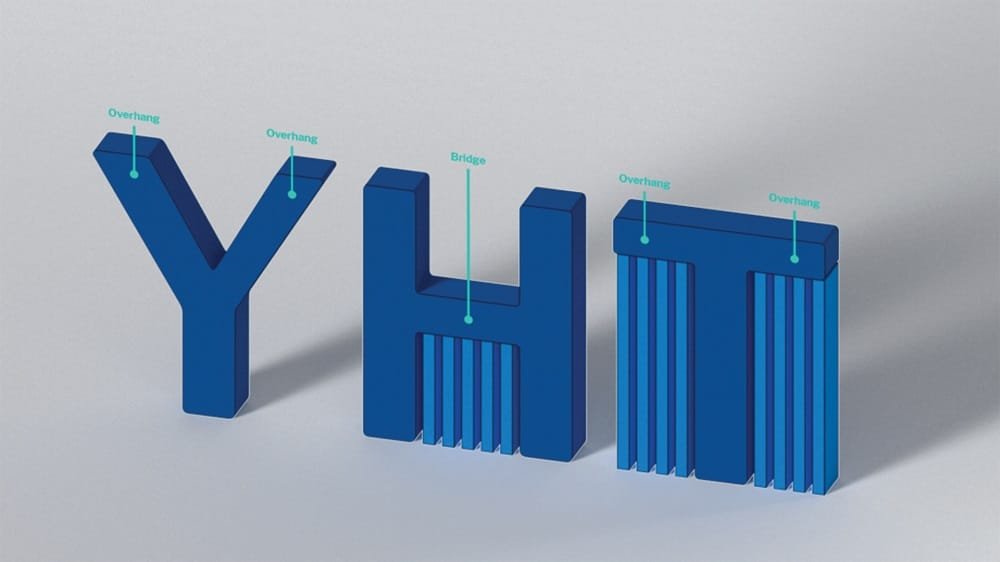

Reducing Supports and Overhangs

Designing models with fewer overhangs reduces the need for support structures, which speeds up printing and reduces material waste. Aim to create self-supporting shapes for faster, cleaner prints.

Software Tools for 3D Model Optimization

Optimizing 3D models for printing is easier with the right tools. Here are some popular software options that help streamline the process:

Blender: Blender is a powerful, free tool that allows users to reduce polygon count, adjust geometry, and clean up models, making it ideal for optimizing designs before printing.

TinkerCAD: TinkerCAD is beginner-friendly and perfect for quick model adjustments like resizing, simplifying shapes, and removing unnecessary details for faster prints.

Fusion 360: Fusion 360 is a professional-grade tool that offers advanced optimization features, including geometry refinement, wall thickness adjustment, and stress analysis, ensuring high-quality prints.

These tools are widely accessible, making it easy for users in India to optimize their 3D models efficiently.

Optimizing 3D Models for Indian Users

For 3D printing enthusiasts in India, model optimization is crucial for balancing cost and quality. Here are a few tips tailored to Indian users:

- Use Affordable Materials

Optimize models to work with budget-friendly filaments like PLA, which are widely available and reliable in the Indian market. Reducing material usage through careful design saves money without compromising print quality.

- Adapt for Common Printer Types

FDM printers are the most popular in India due to their affordability. Design your models with these printers in mind by adjusting layer height, infill, and wall thickness for better speed and efficiency.

- Minimize Post-Processing

To save time and effort, focus on designing models that require minimal supports and post-processing. This approach reduces material waste and speeds up the workflow, especially for those using entry-level printers.

Conclusion

Optimizing 3D models is a critical step for achieving faster printing, reducing costs, and improving the overall quality of your prints. By simplifying geometry, adjusting wall thickness and layer height, and minimizing support structures, you can significantly enhance your 3D printing experience. Indian users, in particular, can benefit from these techniques by using affordable materials and optimizing designs for commonly used printers. Start implementing these tips in your workflow to enjoy more efficient, reliable, and cost-effective 3D printing results.