Enhancing Designs with 3D Scanning Services and CAD Modeling

The combination of 3D scanning and CAD modeling has transformed the way designs are created and improved. 3D scanning captures the exact shape and details of an object, while CAD modeling refines and optimizes the design for production. This powerful duo is essential for 3D printing services, helping to save time, reduce errors, and create more precise products.

By using these technologies together, businesses can achieve better results in manufacturing and prototyping, making the process faster and more efficient. This blog will explore how 3D scanning and CAD modeling enhance designs and drive innovation.

What Are 3D Scanning Services?

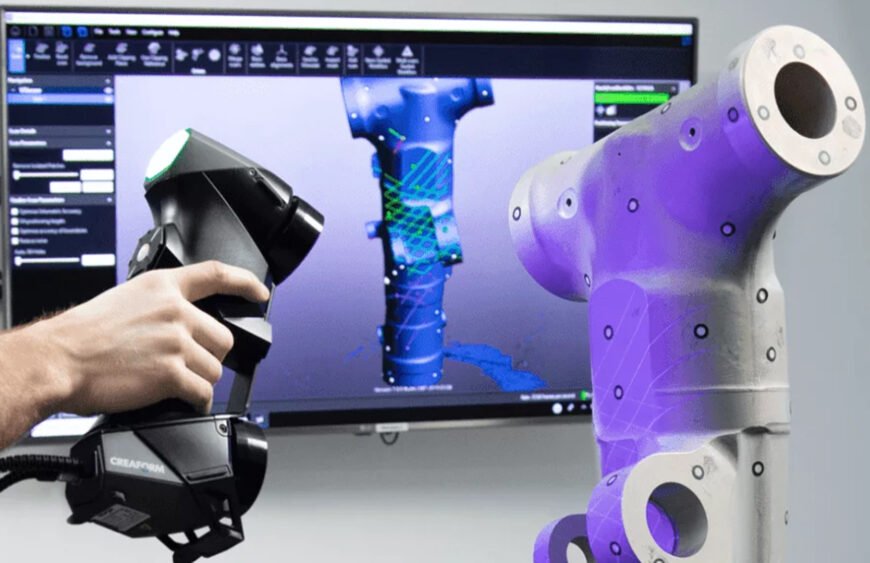

3D scanning services use advanced technology to capture the shape and details of an object and turn it into a digital 3D model. This process is precise, fast, and highly accurate, making it ideal for modern design and manufacturing needs.

How Does 3D Scanning Work?

3D scanners use lasers, structured light, or photogrammetry to scan an object’s surface. The scanner collects data points, which are then processed into a detailed 3D digital model. This model can be used for analysis, design improvements, or 3D printing.

Benefits of 3D Scanning Services

- Accuracy: Captures complex shapes and intricate details.

- Time-saving: Speeds up prototyping and reverse engineering.

- Cost-effective: Reduces material waste and design errors.

- Versatility: Works for objects of all shapes and sizes.

The Role of CAD Modeling in 3D Printing

CAD modeling (Computer-Aided Design) is the process of creating precise 3D models using specialized software. It plays a critical role in turning ideas into ready-to-print designs, especially when combined with 3D scanning.

What is CAD Modeling?

CAD software allows designers to create, modify, and perfect 3D models for manufacturing. When paired with 3D scanning, it refines scanned data to ensure the design meets specific requirements, such as shape, size, and functionality.

Benefits of CAD in 3D Printing

- Design Optimization: Enhances models for specific 3D printing methods and materials.

- Precision and Control: Allows for detailed adjustments and fine-tuning.

- Customization: Makes it easy to adapt designs for unique applications.

- Collaboration: Supports file sharing and real-time edits, improving teamwork.

How 3D Scanning and CAD Modeling Work Together

The integration of 3D scanning and CAD modeling creates a seamless process for design improvement. 3D scanning captures the physical details of an object, which are then imported into CAD software. This digital data is refined and optimized to ensure the design is suitable for manufacturing or 3D printing.

Applications of This Workflow

One key application is reverse engineering, where an object is scanned to create a new digital model for reproduction or improvement. Another is the development of complex designs, where intricate details captured by the scanner are enhanced using CAD tools.

Benefits for 3D Printing Services

This workflow reduces design errors, saves time, and allows for better customization. By combining 3D scanning’s accuracy with CAD modeling’s flexibility, businesses can produce precise, high-quality products that are ready for 3D printing.

Applications in 3D Printing Services

Prototyping and Product Development

3D scanning and CAD modeling streamline the creation of prototypes by quickly capturing accurate data and refining designs. This speeds up the development cycle, allowing for faster testing and iteration. Businesses can create prototypes that closely resemble the final product, reducing time and cost in the production process.

Restoration and Customization

These technologies are vital for restoring damaged or legacy parts. By scanning an object, a digital replica is created, which can then be repaired or modified in CAD software. This is also ideal for creating custom solutions, such as personalized consumer goods or medical devices tailored to individual needs.

Supporting Various Industries

The combination of 3D scanning and CAD modeling is widely used across industries.

- Aerospace and Automotive: For designing lightweight parts and reverse engineering components.

- Healthcare: To create custom prosthetics, implants, and dental models.

- Consumer Goods: For product innovation and personalized manufacturing.

Why Choose Tesseract for 3D Scanning and CAD Modeling?

Expertise in Cutting-Edge Technology

At Tesseract, we specialize in delivering top-notch 3D scanning services and CAD modeling solutions tailored to meet the unique needs of our clients. With years of experience and the latest tools, we ensure accuracy and quality in every project.

Comprehensive Design Solutions

From capturing precise 3D scans to creating optimized CAD models, Tesseract offers a full suite of services. Whether you need reverse engineering, design customization, or prototyping, our team can handle it all, helping you bring your ideas to life.

Proven Success Across Industries

Our expertise spans multiple industries, including aerospace, automotive, healthcare, and consumer goods. Clients trust us for our ability to deliver innovative solutions that improve efficiency and reduce costs.

A Partner You Can Trust

When you work with Tesseract, you gain more than just a service provider—you gain a partner dedicated to helping you succeed. Our commitment to quality, speed, and customer satisfaction ensures your projects are completed on time and to the highest standards.

Conclusion

3D scanning and CAD modeling are revolutionizing design and manufacturing, offering precision, speed, and endless possibilities for 3D printing services. From prototyping to customization, these tools enable businesses to create better products efficiently. At Tesseract, we specialize in combining these technologies to deliver innovative solutions. Contact us today and let’s bring your ideas to life with cutting-edge design expertise.