The 3D printing industry in India is rapidly evolving, with professionals seeking advanced techniques to enhance precision, efficiency, and creativity. From custom manufacturing to prototyping, mastering 3D printing techniques is essential for staying competitive in this dynamic market. Advanced methods allow for greater control over material selection, design optimization, and print quality, enabling professionals to produce intricate, high-quality models. As India continues to embrace this technology, professionals must stay informed about the latest trends and techniques to unlock the full potential of 3D printing in their projects.

Optimizing 3D Printing Materials

Choosing the right material is critical for achieving the desired results in 3D printing. The selection process depends on factors such as strength, flexibility, and temperature resistance, with materials like PLA, ABS, and PETG being commonly used for different applications. Materials like Nylon and TPU offer greater durability and elasticity for advanced projects. In India, the availability of high-quality, locally-produced filaments is growing, providing cost-effective and eco-friendly options. By understanding the properties of these materials and choosing the right one, professionals can enhance both the quality and sustainability of their 3D printing projects.

Advanced 3D Printing Techniques to Improve Precision

Achieving precision in 3D printing is essential for professionals looking to produce high-quality, detailed prints. Below are some advanced techniques to improve accuracy and overall print quality:

Layer Height Optimization

Layer height plays a crucial role in determining the quality and speed of your prints. Optimizing layer height allows you to control the smoothness and detail of your printed models.

- Finer Layer Heights (0.1 mm or less):

- Ideal for highly detailed models requiring smooth surfaces.

- Best used for small, intricate parts or aesthetic pieces where surface finish is a priority.

- Drawback: Longer print times due to more layers being required.

- Thicker Layer Heights (0.2 mm or more):

- Suitable for larger, less detailed parts where speed is more important.

- Reduces print time by using fewer layers.

- Drawback: Coarser surface finish and loss of fine detail.

- Tip for Professionals:

- Choose finer layers for visual parts and thicker layers for functional prototypes, balancing quality with speed based on the project.

Infill Density and Pattern Selection

Infill density and pattern significantly impact the structural integrity and weight of your 3D print. Advanced techniques can help you achieve the best balance between strength and material efficiency.

- Infill Density:

- Low Density (10-20%):

- Reduces material usage and print time.

- Suitable for decorative or non-functional parts.

- High Density (50% or more):

- Increases part strength and weight.

- Ideal for mechanical parts or functional prototypes needing durability.

- Low Density (10-20%):

- Infill Patterns:

- Rectilinear or Grid: Common, fast, and simple patterns that provide basic strength. It is good for everyday prints.

- Honeycomb: Provides excellent strength-to-weight ratio, making it a go-to for stronger prints without excess material use.

- Gyroid: Offers superior strength and flexibility in all directions, making it perfect for complex mechanical parts.

- Tip for Professionals:

- Use a low-density infill for aesthetic models, but opt for a higher density and stronger pattern (like gyroid) for parts requiring strength and durability.

Mastering these advanced techniques ensures that your 3D prints achieve the perfect balance between precision, material usage, and structural integrity. By properly optimizing layer height and infill settings, professionals can significantly enhance the overall quality and performance of their prints.

3D Printing Troubleshooting for Professionals

Even experienced professionals face issues in 3D printing. Here are quick fixes for common problems:

- Warping and Layer Shifting:

- Warping Solutions: Use bed adhesives, maintain a heated bed (60-70°C for PLA), and use an enclosed print chamber.

- Layer Shifting Solutions: Tighten belts, reduce print speed, and ensure the printer is on a stable surface.

- Over-Extrusion/Under-Extrusion:

- Over-Extrusion Fix: Calibrate extruder, adjust flow rate to 90-95%.

- Under-Extrusion Fix: Clean the nozzle, use consistent filament, and check print temperature.

- Stringing/Blobbing:

- Stringing Fix: Increase retraction distance, reduce print temperature.

- Blobbing Fix: Lower flow rate, refine travel moves.

These quick tips will help you troubleshoot and improve print quality efficiently.

3D Design Techniques for Optimizing Prints

Design plays a pivotal role in ensuring a successful 3D print, especially when aiming to reduce material usage, printing time, and post-processing efforts. By incorporating advanced design techniques, professionals can optimize their models for better printability and overall performance.

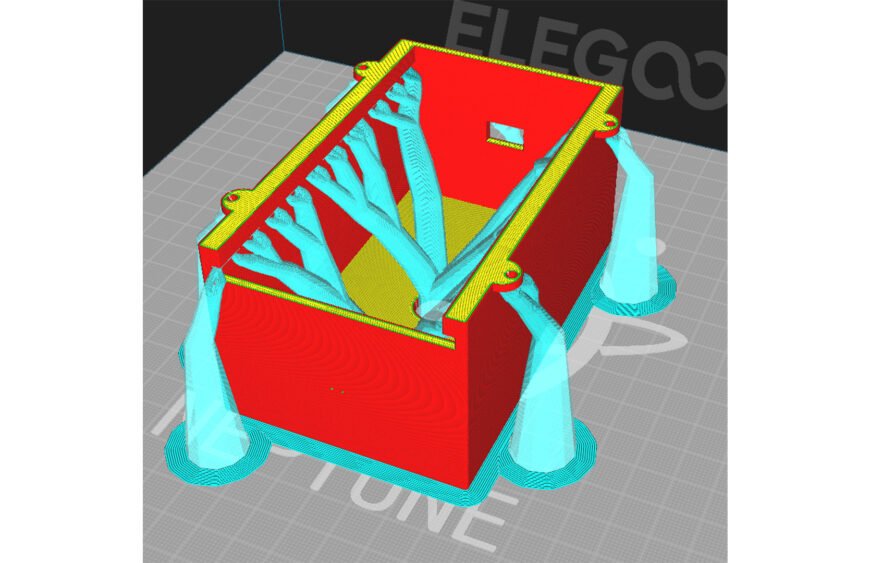

One critical concept is Design for Additive Manufacturing (DFAM), which emphasizes creating 3D models specifically suited for 3D printing. This involves accounting for overhangs, supports, and bridges. By minimizing overhangs and designing parts with angles below 45 degrees, you can often avoid the need for excessive supports, reducing both material waste and post-processing time. When supports are unavoidable, ensure they are designed for easy removal and minimal contact with the model’s surface.

Another technique is reducing post-processing through smart design. Incorporating features like chamfers, fillets, and rounded edges not only improves the model’s strength but also minimizes the need for extensive sanding or smoothing afterward. Designing with the orientation of the print in mind can also reduce surface imperfections, as certain geometries lend themselves better to specific printing angles.

Additionally, integrating tolerances into your design is essential, especially when creating interlocking or moving parts. A proper understanding of printer capabilities and material shrinkage helps ensure that parts fit together seamlessly without the need for excessive trial and error.

Conclusion

Mastering advanced 3D printing techniques is essential for professionals seeking high-quality, efficient results. From optimizing material selection and layer heights to troubleshooting common issues and applying smart design techniques, these strategies can dramatically improve print precision and reduce time and material waste. As 3D printing continues to evolve, especially in the Indian market, staying updated with the latest advancements and continuously refining your skills will help you stay competitive and deliver superior projects.