Nylon 3D printing is revolutionizing the manufacturing industry with its unmatched strength, flexibility, and durability. Known for being lightweight and resistant to wear, nylon is a versatile material ideal for creating functional prototypes, industrial parts, and custom tools. Its ability to endure stress and harsh environments makes it a top choice for industries like automotive, aerospace, and consumer goods. Whether you need long-lasting components or reliable performance, Nylon 3D Printing offers exceptional results that stand the test of time.

Why Durability Is Important in 3D Printing

Durability is a critical factor in 3D Printing, especially for parts designed for practical or industrial use. Fragile materials can fail under stress, leading to additional costs for replacements or repairs. Durable 3D printed components, like those made with nylon, ensure longer lifespans, greater reliability, and better performance in challenging conditions. Whether it’s a prototype or an end-use product, durability translates to consistent functionality and reduced maintenance.

Industries That Rely on Durable 3D Prints

- Automotive: Nylon’s strength and flexibility make it ideal for manufacturing durable gears, clips, and housings that endure repetitive motion and stress.

- Aerospace: Lightweight yet robust, nylon is used for components that must handle pressure and extreme conditions.

- Consumer Products: From household tools to sports equipment, nylon ensures wear-resistant and long-lasting products that meet daily demands.

Why Nylon is Perfect for Durable 3D Printing

Nylon stands out as a 3D printing material for its unique combination of strength, flexibility, and resistance to wear. These properties make it ideal for producing parts that need to last, even in demanding environments.

Tough Against Impact

Nylon offers excellent impact resistance, making it suitable for parts that might experience sudden shocks or stress. Unlike brittle materials such as PLA, nylon absorbs and dissipates force without cracking or breaking. This makes it ideal for components like protective casings, structural parts, and mechanical tools.

Flexible and Adaptable

Nylon has a natural flexibility that prevents it from breaking under tension. This is especially useful for parts like hinges, clips, or items that need to bend during use. Its ability to maintain structural integrity under repeated motion ensures a longer lifespan for moving components.

Resistant to Wear and Tear

One of nylon’s standout features is its resistance to abrasion and friction. In applications where parts interact with each other or with moving surfaces, nylon excels at maintaining its shape and performance. For example, gears, bushings, and other mechanical elements benefit greatly from nylon’s durability.

Comparing Nylon to Other 3D Printing Materials

While several materials are available for 3D printing, nylon stands out due to its unique combination of properties. Here’s how it compares to other popular choices:

Nylon vs PLA and ABS

- Strength and Durability: Nylon outperforms PLA and ABS in tensile strength and flexibility, making it ideal for load-bearing applications.

- Heat Resistance: PLA is prone to deforming under heat, while ABS offers some resistance but doesn’t match nylon’s stability in high-temperature environments.

- Wear and Tear: Nylon is far more resistant to friction and abrasion compared to PLA and ABS, ensuring longer-lasting parts.

Nylon vs PETG

- Use-Case Scenarios: PETG is a good option for projects requiring chemical resistance and minimal flexibility, but it lacks nylon’s superior durability and impact resistance.

- Load-Bearing Applications: Nylon’s ability to handle stress and pressure without cracking makes it the better choice for industrial and functional parts.

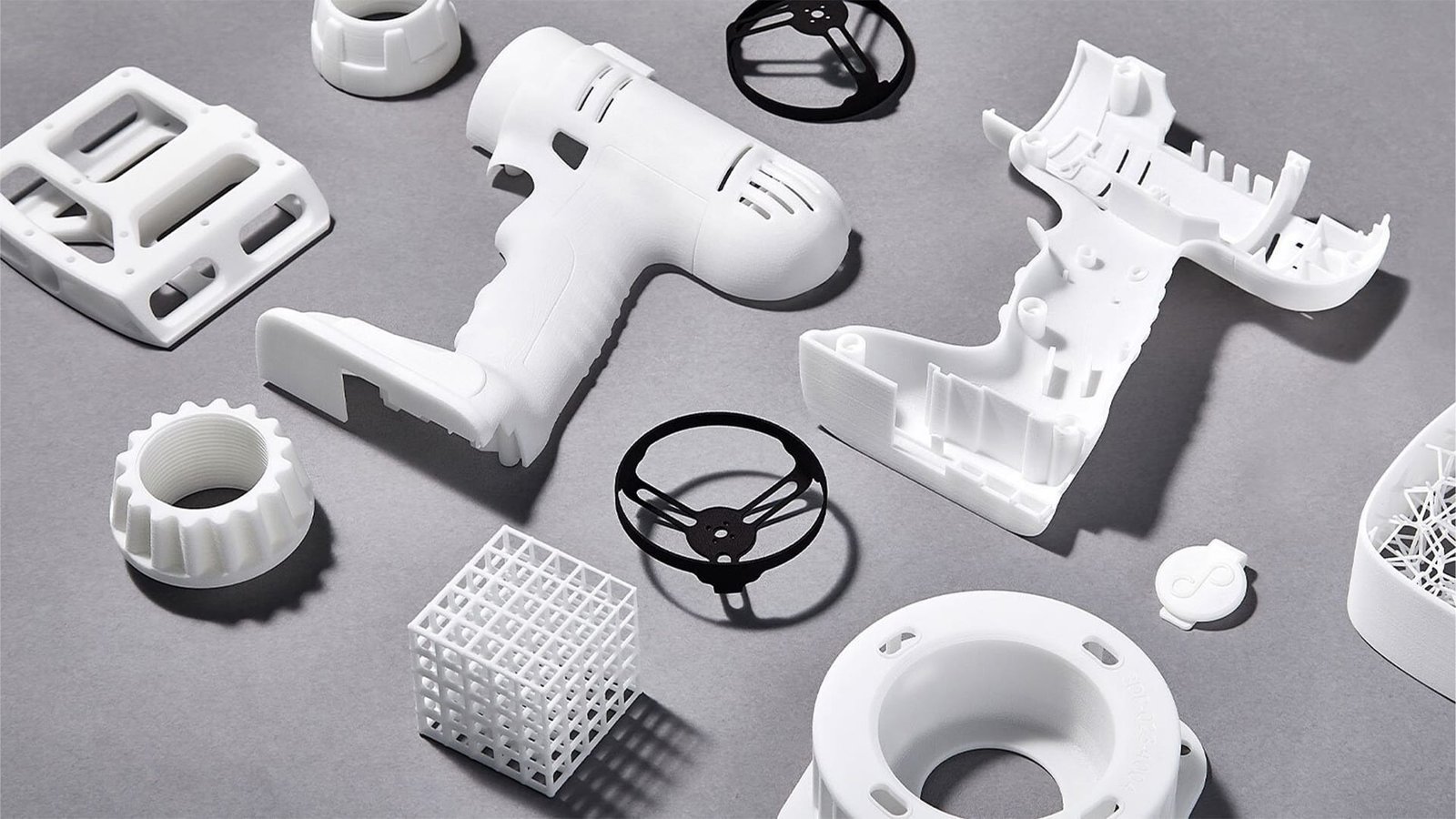

Where Durable Nylon Prints are Used

Nylon’s exceptional durability and flexibility make it a versatile material for various applications. From everyday products to heavy-duty industrial parts, nylon ensures reliable performance and long-lasting results.

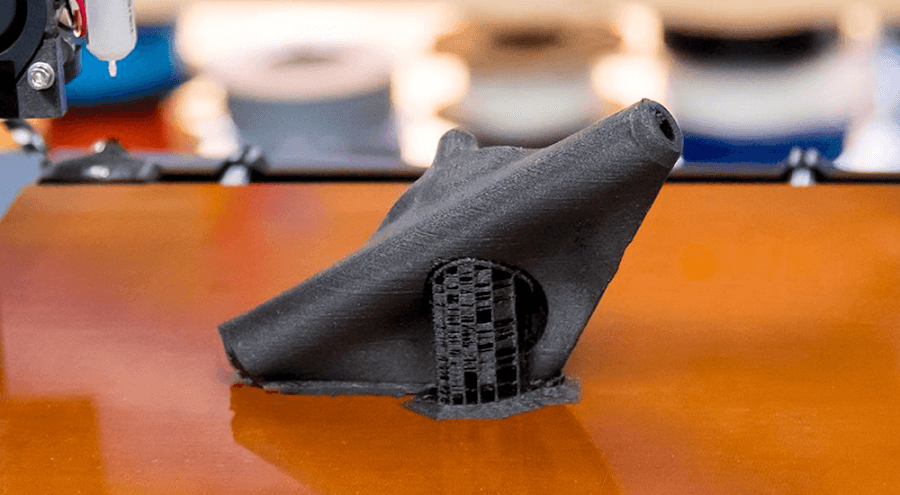

Prototypes That Last

Nylon is a top choice for creating functional prototypes that need to withstand real-world testing. Whether it’s stress testing in a lab or hands-on evaluation in the field, nylon prototypes can handle tough conditions without breaking, giving engineers and designers the confidence to move forward with production.

End-Use Parts for Long-Term Use

- Machinery Components: Nylon’s strength and wear resistance make it perfect for gears, bushings, and other moving parts that must endure constant motion.

- Custom Tools and Fixtures: Nylon is commonly used for jigs, fixtures, and specialized tools, thanks to its ability to maintain shape and function over time.

- Consumer Products: Durable nylon is ideal for creating items like sports equipment, phone cases, or household tools that need to stand up to daily use.

Conclusion

Nylon 3D printing offers unparalleled durability, flexibility, and strength, making it an ideal choice for industries and applications requiring reliable, long-lasting components. Its ability to withstand wear, impact, and challenging environments sets it apart from other 3D printing materials like PLA and ABS. Whether you’re creating prototypes, industrial parts, or everyday tools, nylon ensures consistent performance and reduced maintenance costs.

Ready to explore the benefits of nylon 3D printing? Partner with Tesseract for top-quality, durable parts tailored to your needs. Contact us today!