Ceramic Stereolithography

Unlocking Formability

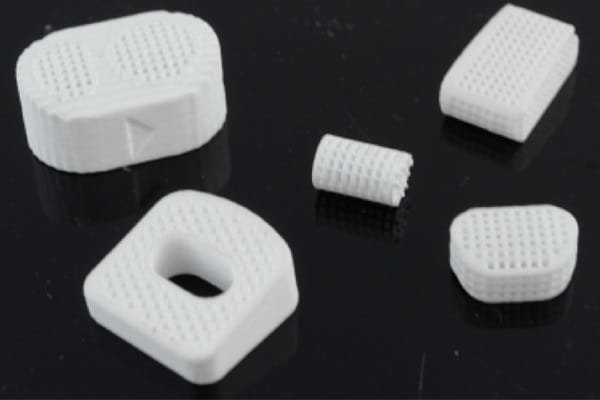

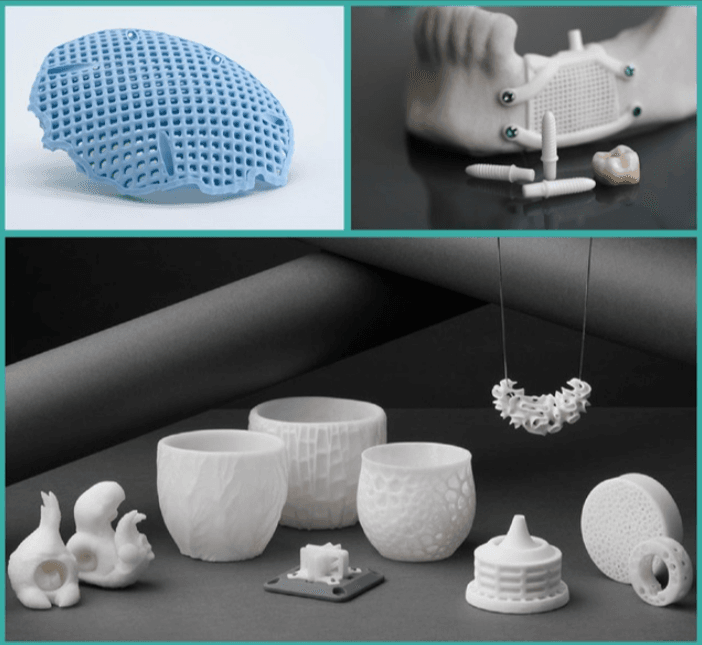

Ceramic Stereolithography, also known as Ceramic Additive Manufacturing (C-AM), is poised to revolutionise ceramics’ processing and formability challenges. It fabricates structures by slicing 3D Models and stacking ceramic materials layer-by-layer without the need for moulds or extensive machining.

USP

High Precision

Superior Finish Quality

Wide Range of Materials

Fast Production

Simplified Workflow

Biocompatibility Certifications

Our Post Processing Offerings

Our Material Offerings

Industries

Why Choose Tesseract for Ceramic Stereolithography (CSL)?

At Tesseract, we specialize in delivering cutting-edge 3D printing solutions, and Ceramic Stereolithography (CSL) is at the forefront of our capabilities. Leveraging the latest in additive manufacturing technology, Tesseract offers unparalleled precision, quality, and efficiency for industries ranging from aerospace and automotive to healthcare and industrial design. Our CSL services are designed to push the boundaries of innovation, providing you with a trusted partner for all your ceramic manufacturing needs.

Tesseract’s Ceramic Stereolithography Capabilities

High Precision

Tesseract’s CSL technology enables exceptional accuracy, down to micron-level precision. This makes it ideal for producing complex geometries and fine details that are often challenging with traditional manufacturing methods.

Superior Finish Quality

Achieve smooth surfaces and sharp details that are unmatched by other 3D printing techniques. Our proprietary post-processing techniques ensure that your ceramic parts have a flawless finish, enhancing both aesthetics and performance.

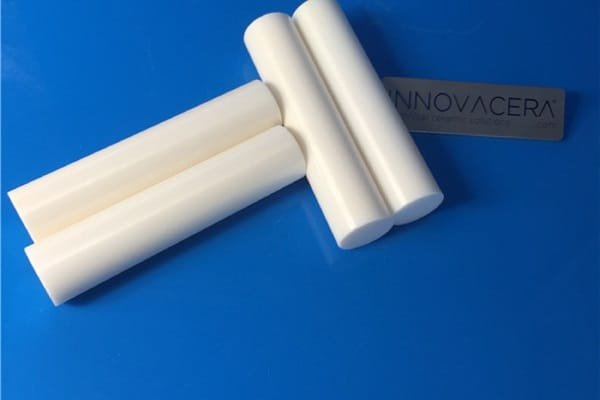

Wide Range of Materials

We offer an extensive selection of high-performance ceramic materials, each suited for different industrial applications. Whether it’s alumina, zirconia, or silicon nitride, our materials are engineered to meet your specific project requirements.

Fast Production

Our state-of-the-art 3D printing systems allow for rapid production without compromising on quality. Reduce lead times and accelerate time-to-market for your products with Tesseract’s efficient manufacturing process.

Simplified Workflow

Tesseract’s streamlined design-to-production process simplifies the complexities of traditional manufacturing. Our experienced team manages everything from concept to delivery, ensuring a smooth experience and exceptional results.

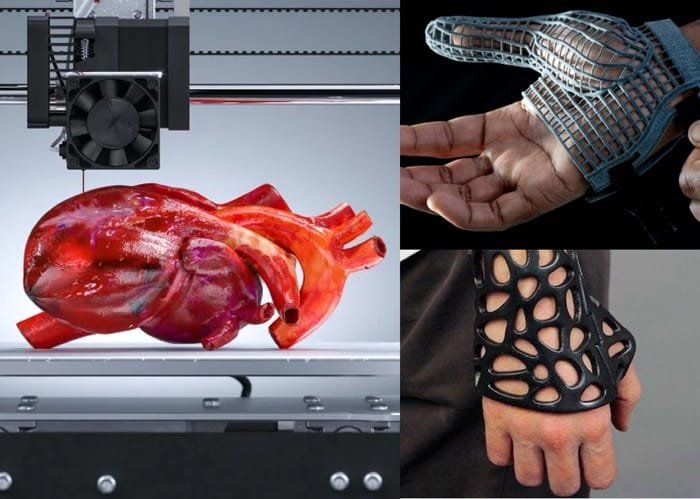

Biocompatibility Certifications

For industries requiring biocompatible materials, Tesseract offers ceramic 3D printing solutions that meet stringent regulatory standards, making them suitable for medical and dental applications.

Partner with Tesseract for Innovative Ceramic Solutions

Choosing Tesseract for your ceramic stereolithography needs means partnering with a company committed to precision, quality, and innovation. We bring years of expertise and a deep understanding of advanced manufacturing to help you transform your ideas into tangible, high-performance products. From intricate prototypes to large-scale production, Tesseract is your go-to partner for ceramic 3D printing.

Let us bring your vision to life with precision and excellence.