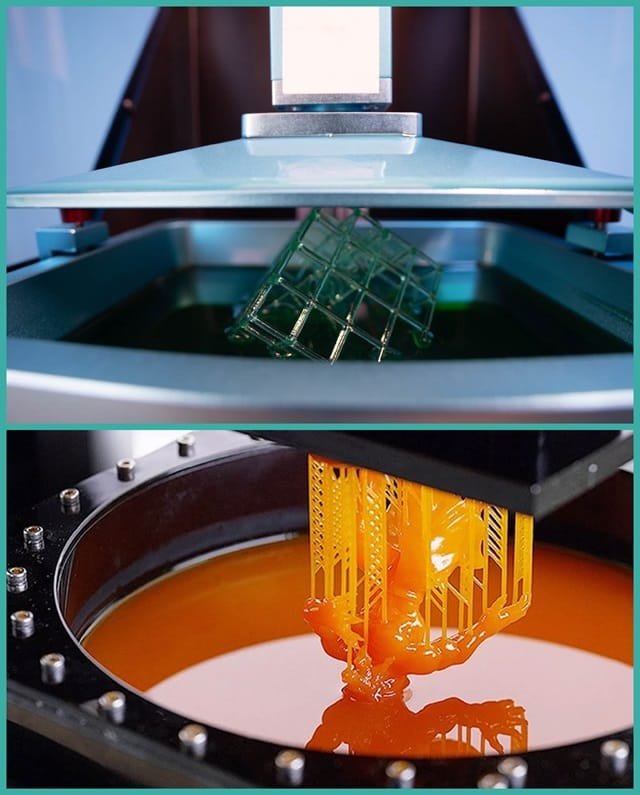

DLP (Digital Light Processing)

Unlocking Speed

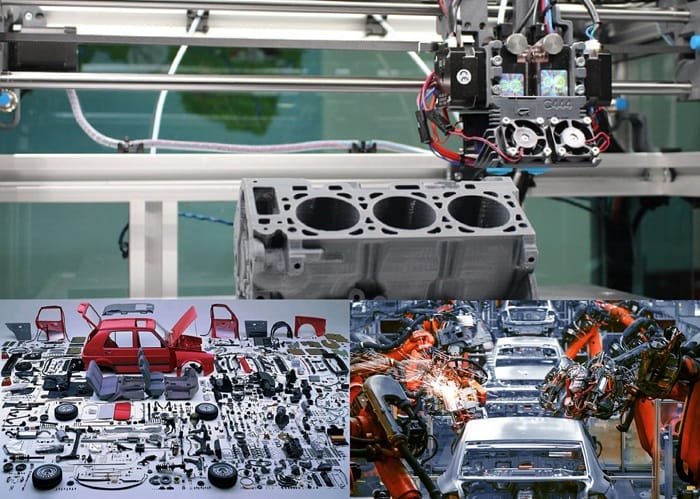

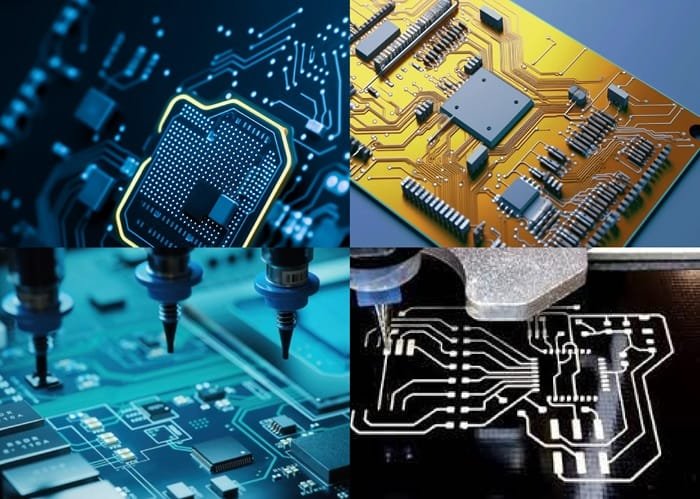

Digital Light Processing (DLP), a form of 3D Printing akin to SLA, utilises a photopolymer resin tray exposed to light from a projector. Each 3D model layer is projected onto the resin, hardening the exposed area, and the process repeats until the model is complete. DLP machines excel in speed, making them a preferred choice for intricate part production, particularly in industries requiring small quantities of multiple designs produced quickly, and can be efficiently integrated into traditional production methods. This digital moulding process ensures the strength, accuracy, reliability, repeatability, and uptime of traditional moulding while eliminating the costs and time-consuming aspects of tooling.

USP

Exceptional Finish

Remarkable Resolution

Rapid Production

Ideal for Complex Designs

Biocompatibility Certifications

Our Post Processing Offerings

Our Material Offerings

Industries

Why Choose Tesseract for Your Digital Light Processing (DLP) Needs?

When it comes to Digital Light Processing (DLP) technology, Tesseract stands out as a leader in innovation, precision, and customer satisfaction. Our expertise in 3D printing and designing, combined with our commitment to excellence, makes us the preferred partner for all your DLP requirements. Here’s why Tesseract should be your go-to choice:

Exceptional Finish

At Tesseract, we ensure that every print boasts an exceptional finish. Our DLP technology delivers smooth surfaces and fine details, reducing the need for post-processing. This means your products look professional straight out of the printer, saving you time and resources.

Remarkable Resolution

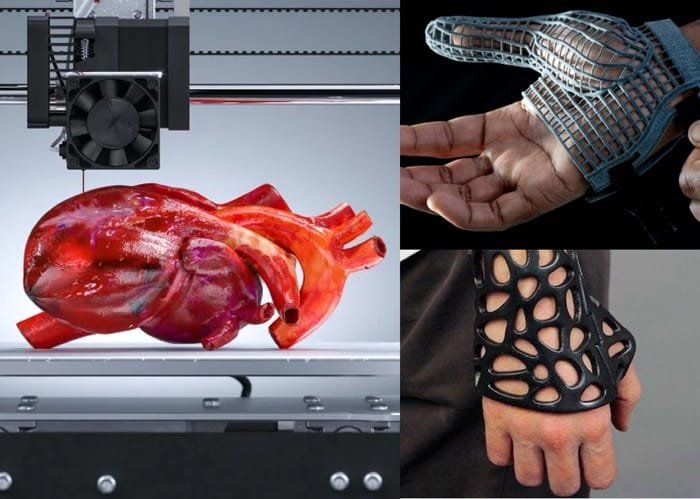

Our DLP printers offer remarkable resolution, capturing even the minutest details with high precision. This capability is crucial for industries requiring intricate designs and exacting standards, such as jewelry, dental models, and intricate prototypes.

Rapid Production

Time is money, and our DLP technology significantly reduces production times. Tesseract’s DLP printers can quickly produce high-quality parts, enabling faster iterations and quicker time-to-market for your products. Whether you need a single prototype or a small batch of products, our rapid production capabilities ensure you meet your deadlines.

Ideal for Complex Designs

Tesseract excels in handling complex designs that are challenging for traditional manufacturing methods. Our DLP technology can create intricate geometries and detailed structures with ease, allowing you to push the boundaries of creativity and innovation.

Biocompatibility Certifications

We understand the importance of safety and compliance, especially in the medical and dental fields. Tesseract’s DLP materials come with biocompatibility certifications, ensuring that your products meet stringent health and safety standards. This makes our technology ideal for producing dental aligners, surgical guides, and other medical devices.

Choosing Tesseract for your DLP needs means partnering with a company that prioritizes quality, precision, and customer satisfaction. Our cutting-edge technology, combined with our industry expertise, ensures that you receive the best solutions for your 3D printing and designing projects. Experience the future of DLP with Tesseract—where innovation meets excellence.