DMLS (Direct Metal Laser Sintering)

Unlocking Flexibility

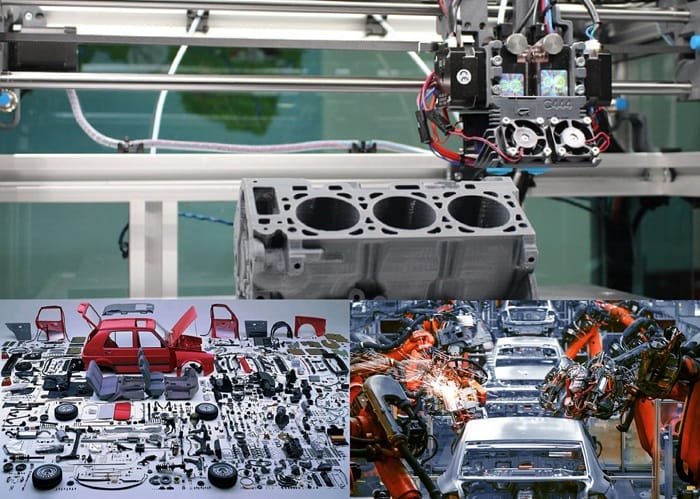

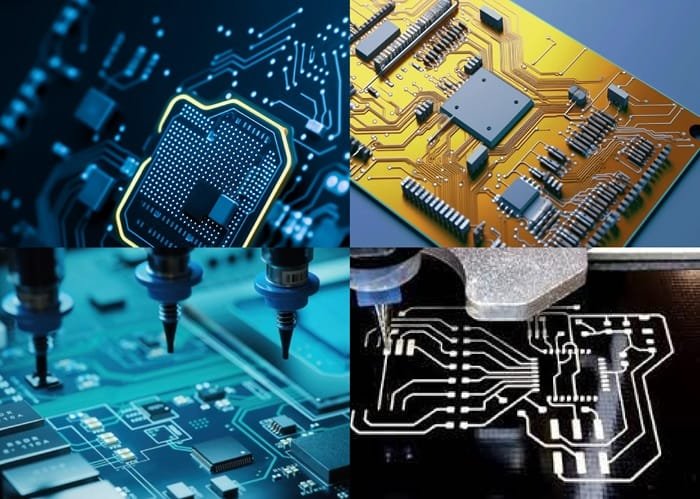

Direct Metal Laser Sintering (DMLS), a specialised form of SLS, leverages high-wattage lasers to micro-weld powdered metals and alloys into fully functional metal structures and components. DMLS excels in shaping materials like Aluminum, Stainless Steel, MS, Titanium, and more, providing denser and superior parts. With its limitless design potential, DMLS is a game-changer for industries such as Oil & Gas, Aerospace, Automotive, Defense, and Medical where compact components with highly complex anatomical shapes, internal channels, and complex surface textures are a requirement.

USP

Rapid Complex Metal Fabrication

Eliminating Tooling

Wide Range of Materials

Optimised Functionality

Enhanced Surface Finish

Biocompatibility Certifications

Our Post Processing Offerings

Our Material Offerings

Industries

Why Choose Tesseract for DMLS (Direct Metal Laser Sintering)?

At Tesseract, we stand at the forefront of innovation in 3D printing and design, delivering unparalleled solutions through Direct Metal Laser Sintering (DMLS). Our commitment to excellence, precision, and quality makes us the preferred choice for your metal 3d printing and metal component manufacturing needs. Here’s why partnering with Tesseract ensures your projects achieve the highest performance and reliability standards.

Rapid Complex Metal Components Fabrication

With DMLS technology, Tesseract can produce intricate and complex metal parts swiftly, allowing for quick turnarounds and meeting the most demanding project timelines. Our advanced machinery and expertise ensure that even the most complicated designs are fabricated accurately and efficiently.

Eliminating Tooling

DMLS eliminates the need for traditional tooling, reducing costs and production times. This cutting-edge process allows us to manufacture parts directly from digital designs, streamlining the entire fabrication process and enhancing overall productivity.

Wide Range of Materials

We offer a vast selection of materials to suit various applications, from high-strength alloys to specialty metals. Whether you need stainless steel, titanium, or nickel-based superalloys, Tesseract has the capability to meet your material specifications with precision.

Optimized Functionality

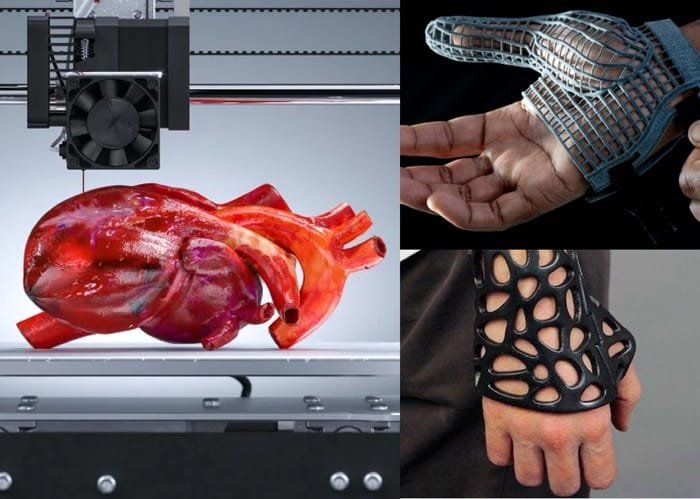

Our DMLS process not only creates parts with exceptional mechanical properties but also allows for the optimization of functionality. By integrating complex geometries and internal structures, we ensure that your components deliver superior performance and durability.

Enhanced Surface Finish

At Tesseract, we understand the importance of surface finish in the functionality and aesthetics of your parts. Our DMLS technology produces parts with excellent surface quality, reducing the need for post-processing and delivering components that are ready to use. We can do additional post processing as required.

Biocompatibility Certifications

For industries such as medical and dental, biocompatibility is crucial. Tesseract’s DMLS materials are certified for biocompatibility, ensuring that our metal parts meet stringent health and safety standards, making them ideal for implants, prosthetics, and other medical applications.

Support

Our dedicated team of experts is always ready to provide comprehensive support throughout your project. From initial consultation and design optimization to production and post-processing, we work closely with you to ensure your requirements are met with precision and expertise.

Speed

Tesseract’s DMLS technology accelerates production cycles, delivering high-quality metal parts in record time. Our efficient processes and state-of-the-art equipment enable us to meet tight deadlines without compromising on quality.

Choose Tesseract for your DMLS needs and experience the future of metal fabrication today. With our advanced technology, wide range of materials, and commitment to excellence, we deliver solutions that drive innovation and success in every project. Partner with Tesseract and unlock the full potential of Direct Metal Laser Sintering for your business.

FAQ

DMLS (Direct Metal Laser Sintering) uses high-wattage lasers to micro-weld metal powders layer by layer, creating fully functional metal parts with complex geometries and superior density.

We work with Aluminum, Stainless Steel, Mild Steel, Titanium, and various other metal alloys, each selected based on your specific application requirements.

DMLS is ideal for the oil and gas, Aerospace, Automotive, Defense, and Medical industries that require compact components with complex internal channels, anatomical shapes, and intricate surface textures.

DMLS offers unlimited design freedom, produces denser and stronger parts, eliminates tooling costs, reduces material waste, and enables the rapid prototyping of complex geometries that are impossible with traditional manufacturing methods.

Yes, we accommodate single-piece prototypes for testing as well as production runs, with turnaround times typically ranging from a few days to 2-3 weeks, depending on complexity.