3D printed electronics combine traditional 3D printing with conductive materials to create functional electronic devices. This innovative approach allows for integrating electronic components directly into 3D printed structures. Evolving from basic prototyping, 3D printed electronics now enable complex designs and rapid production. This technology opens new possibilities in custom electronics, offering design flexibility and cost efficiency, driving innovation across various industries.

Advantages of Integrating Electronics with 3D Printing

Customization and Design Flexibility

3D printed electronics offer unparalleled customization and design flexibility, allowing designers to create complex and unique structures tailored to specific needs. This capability is particularly beneficial for producing bespoke medical devices and custom consumer electronics.

Cost-Effective Prototyping and Production

By reducing material waste and production time, 3D printed electronics provide a cost-effective solution for prototyping and mass production. This efficiency is crucial for startups and established companies looking to innovate without incurring high costs.

Rapid Prototyping for Innovation

The ability to quickly prototype and test new designs accelerates the innovation process. 3D printed electronics enable rapid iterations, helping companies bring new products to market faster and stay competitive in a rapidly evolving technological landscape.

Real-World Applications in Various Industries

Healthcare and Medical Devices

In healthcare, 3D printed electronics are revolutionizing medical devices. Custom implants, prosthetics, and wearable health monitors can be designed to fit individual patients perfectly, enhancing comfort and effectiveness.

Aerospace and Defense

The aerospace and defense industries benefit from 3D printed electronics through lightweight, high-performance components. This technology allows for the creation of complex, integrated systems that reduce weight and increase functionality, crucial for both space missions and defense applications.

Consumer Electronics and Wearables

Consumer electronics and wearables are experiencing a transformation with 3D printed electronics. This technology enables the production of custom-fit devices, such as smartwatches and fitness trackers, that are aesthetically pleasing and ergonomically superior.

Automotive Industry

The automotive industry utilizes 3D printed electronics to produce complex, integrated parts that enhance vehicle performance and reduce manufacturing costs. From custom dashboard interfaces to advanced sensor systems, this technology supports the creation of smarter, more efficient vehicles.

Key Technologies in 3D Printed Electronics

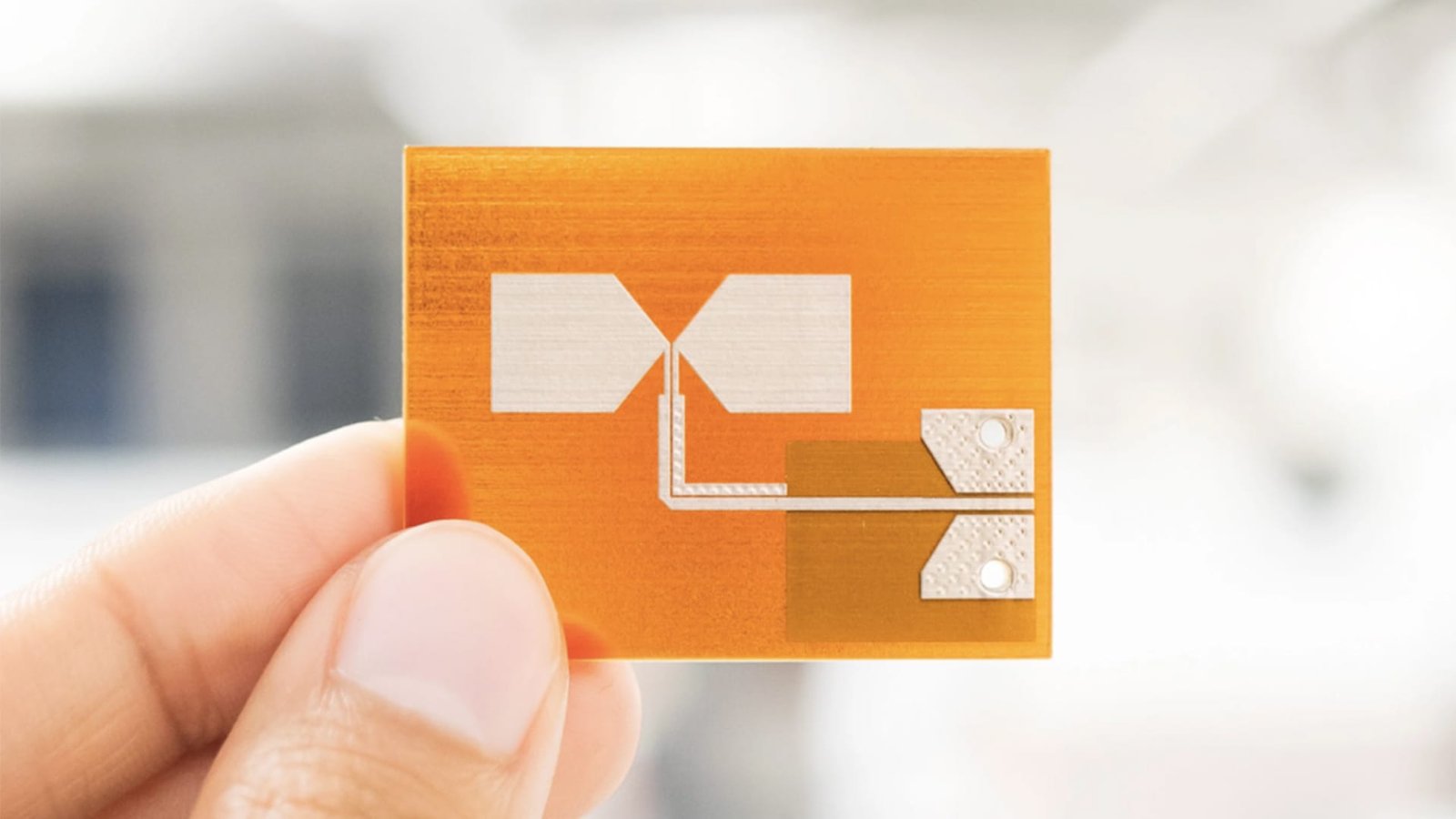

Conductive Inks and Filaments

Conductive inks and filaments are essential for 3D printed electronics, allowing the creation of circuits and electronic components within 3D printed structures. These materials enable the integration of electrical functionality directly into complex shapes and forms.

Multi-Material 3D Printing

Multi-material 3D printing combines various materials in a single print, facilitating the creation of electronic devices with both structural and conductive elements. This technology supports the development of more sophisticated and functional electronic products.

Hybrid Manufacturing Processes

Hybrid manufacturing processes merge traditional and additive manufacturing techniques, enhancing the capabilities of 3D printed electronics. This approach allows for greater precision and complexity, enabling the production of advanced electronic components and devices with improved performance and reliability.

The Future of 3D Printed Electronics

Emerging Technologies and Innovations

The continuous emergence of new technologies and innovations marks the future of 3D printed electronics. Advances in nanotechnology, conductive materials, and multi-material printing are expected to enhance the capabilities and applications of 3D printed electronics. Innovations such as flexible and stretchable electronics are set to revolutionize industries by enabling new forms of wearable technology and smart devices.

Impact on Manufacturing and Design

3D printed electronics are poised to transform manufacturing and design practices. By integrating electronics directly into 3D printed structures, manufacturers can create more efficient, lightweight, and complex products. This shift will lead to streamlined production processes, reduced waste, and the ability to produce highly customized items on-demand, significantly impacting industries like automotive, aerospace, and consumer electronics.

Potential Growth in the Indian Market

India, with its burgeoning tech industry and growing emphasis on innovation, is well-positioned to become a leader in 3D-printed electronics. Government initiatives supporting digital manufacturing and startups, along with a strong educational focus on engineering and technology, provide a fertile ground for the growth of this sector. As awareness and accessibility of 3D printing technology increase, Indian companies can leverage these advancements to drive local manufacturing and compete on a global scale.

Conclusion

3D printed electronics represent a significant technological leap, offering unparalleled customization, cost-effective production, and rapid prototyping. With applications across healthcare, aerospace, consumer electronics, and automotive industries, this innovative approach is transforming manufacturing and design. As emerging technologies continue to evolve, and with India’s growing emphasis on tech innovation, the future of 3D printed electronics looks promising, heralding a new era of advanced, integrated electronic devices.