How 3D CAD Design Services Streamline Engineering Processes

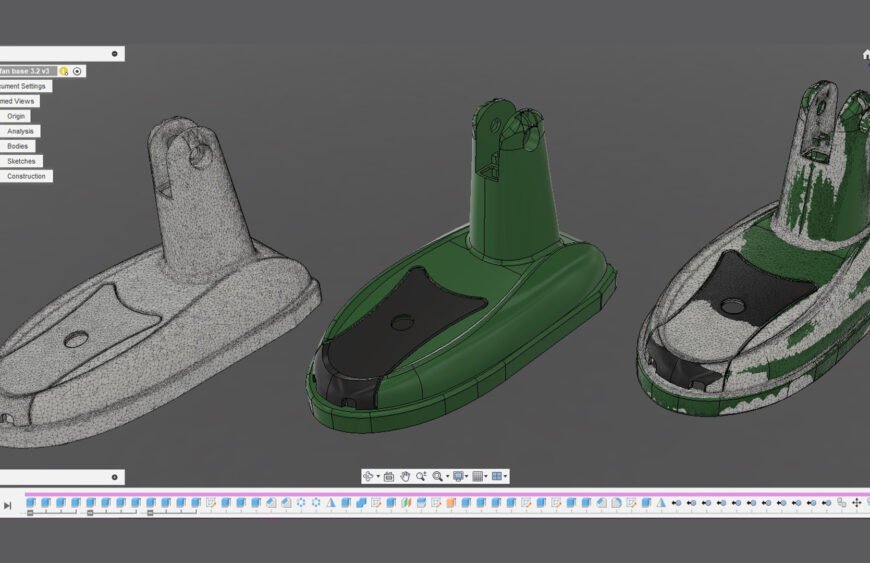

In modern engineering, 3D CAD (Computer-Aided Design) services are essential for accelerating product development and improving design accuracy. Unlike traditional 2D drawings, 3D CAD models offer precise, detailed, and interactive representations of parts and assemblies, enabling faster iterations and reducing errors before manufacturing.

These services streamline workflows by enhancing design precision, enabling real-time collaboration, and integrating seamlessly with manufacturing processes like CNC machining and 3D printing. From concept to production, 3D CAD services optimize every stage of engineering, making them invaluable for industries seeking innovation, efficiency, and cost reduction. This blog explores their key benefits and real-world applications.

Benefits of 3D CAD Design Services in Engineering Processes

Enhanced Design Precision and Error Reduction

3D CAD design services enable engineers to create highly detailed and precise models, ensuring accuracy from the start. Advanced CAD software allows for in-depth geometric modeling and tolerancing, which helps detect potential design flaws early. This minimizes costly errors during production and ensures high-quality outcomes.

Faster Prototyping and Iteration Cycles

With 3D CAD, engineers can quickly generate multiple design iterations, significantly speeding up the prototyping phase. These digital designs integrate seamlessly with 3D printing and other rapid prototyping technologies, allowing faster testing, validation, and refinement of concepts.

Improved Cost Efficiency

Accurate CAD models reduce material waste, lower the number of physical prototypes needed, and streamline production processes. These efficiencies lead to significant cost savings in both the design and manufacturing phases.

Enhanced Product Visualization

3D CAD allows for realistic visualization of products before they are built. Engineers can use photorealistic rendering and animations to better communicate design intent, enabling stakeholders to make informed decisions early in the development process.

Better Design Customization and Flexibility

Parametric design features in 3D CAD software allow for easy modification and customization of designs. Engineers can quickly make changes to dimensions and features, enabling tailored solutions without starting from scratch.

Streamlining Collaboration with Cloud-Based 3D CAD Platforms

Collaboration is a critical aspect of modern engineering projects, where teams often consist of professionals from different disciplines working across various locations. Cloud-based 3D CAD platforms have revolutionized the way teams collaborate by enabling real-time design sharing and updates.

Real-Time Collaboration and Remote Access

Cloud-enabled CAD solutions allow engineers, designers, and manufacturers to work simultaneously on a single design file. Changes made by one team member are instantly visible to others, ensuring everyone stays aligned throughout the project. This eliminates the delays caused by version mismatches or file transfers.

Centralized Data Management and Version Control

Cloud platforms offer centralized data storage, making it easier to manage large volumes of design files. Advanced version control features help track changes, ensuring that teams always work on the latest iteration while maintaining access to previous versions when needed.

Seamless Communication Across Teams

By integrating cloud-based 3D CAD platforms with communication tools, teams can easily share feedback, annotate designs, and resolve issues faster. This leads to quicker decision-making and improved project efficiency.

Scalability for Large and Distributed Teams

Whether it’s a small startup or a global enterprise, cloud-based 3D CAD platforms offer scalability, allowing businesses to expand their operations without investing heavily in infrastructure. Teams across different geographies can collaborate seamlessly, boosting productivity and innovation.

Integration of 3D CAD with Digital Manufacturing and 3D Printing

Direct Integration with Digital Manufacturing, 3D CAD design services streamline the transition from design to production by enabling direct export of CAD files into digital manufacturing systems. These files can be used for CNC machining, injection molding, and other automated processes, reducing manual intervention and errors during production setup.

Optimized Design for 3D Printing

3D CAD tools support Design for Additive Manufacturing (DfAM), ensuring designs are optimized for 3D printing. Engineers can create complex geometries, lightweight structures, and internal features that are difficult or impossible to achieve with traditional manufacturing.

Advanced Simulation for Manufacturing Feasibility

Many 3D CAD platforms include built-in simulation tools, allowing engineers to test stress, heat, and motion before manufacturing. These simulations help ensure manufacturability and product durability, preventing costly design revisions.

Faster Production Cycles and Customization

With direct integration into digital manufacturing and 3D printing, businesses can achieve faster production cycles and easily customize designs for specific client needs. This approach is particularly beneficial for low-volume, high-complexity parts.

Conclusion – The Future of 3D CAD Design Services in Engineering

3D CAD design services have transformed engineering by improving design accuracy, speeding up prototyping, enhancing collaboration, and integrating seamlessly with digital manufacturing technologies. From precise modeling and rapid iterations to cloud-based teamwork and optimized manufacturing, these services streamline the entire product development process.

As 3D CAD technology continues to evolve, innovations such as AI-driven design, generative modeling, and virtual reality integration will further enhance engineering efficiency. Businesses that adopt advanced 3D CAD services gain a competitive edge by reducing costs, improving product quality, and accelerating time-to-market, making them essential for modern engineering success.