Selective Laser Sintering (SLS)

Unlocking Accuracy

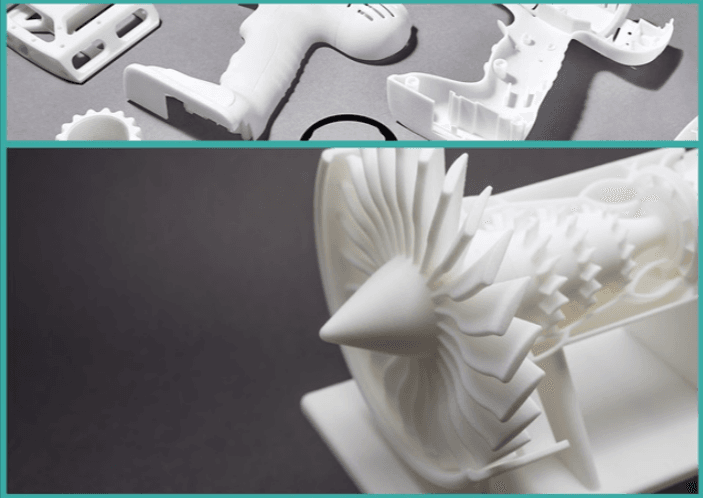

Selective Laser Sintering (SLS), a member of the Powder Bed Fusion family, is a leading industrial 3D printing process. By precisely sintering polymer powder particles layer by layer using a laser, SLS technology brings CAD designs to life, making it a preferred choice for both end-use part manufacturing and prototyping.

USP

Support-Free Printing

Minimal Post Processing

Versatile Geometries

Customisation

Functional Prototypes

Impact Resistance

Low Volume Production

Our Post Processing Offerings

Our Material Offerings

Industries

Why Choose Tesseract for Selective Laser Sintering (SLS)?

At Tesseract, we are dedicated to pushing the boundaries of 3D printing technology, and our expertise in stereolithography (SLA) sets us apart as industry leaders. SLA stereolithography is a revolutionary additive manufacturing process that uses a laser to cure liquid resin into solid 3D objects with incredible precision. Whether you’re developing prototypes, functional parts, or intricate models, Tesseract’s stereolithography 3D printing services offer unmatched quality and reliability.

SLA 3D Printing Applications & Use Cases

EXCEPTIONAL DETAIL

Our SLA printing technology captures the finest details, creating parts with intricate features and smooth surfaces. This precision makes it ideal for applications requiring high accuracy, such as dental models, jewelry, and complex prototypes.

VERSATILE SIZING

Tesseract’s resin 3D printing capabilities can accommodate a wide range of sizes, from small, intricate pieces to larger models up to 1500mm in length. This versatility allows us to meet diverse client needs across various industries.

OUTSTANDING RESOLUTION

With layer thicknesses as fine as 25 microns, our stereolithography 3D printing services produce parts with exceptional resolution. This high level of detail ensures that your designs are faithfully reproduced, from the smallest features to the overall geometry.

QUALITY SURFACE FINISH

Our SLA 3D printing parts boast superior surface finishes, reducing the need for extensive post-processing. The smooth and glossy finish of our SLA prints enhances the aesthetic appeal and functionality of the final product.

MINIMAL SHRINKAGE/WARPING

SLA printing processes minimize shrinkage and warping, ensuring dimensional stability and accuracy. This consistency is crucial for parts that require tight tolerances and precise fitment.

RAPID TURNAROUND TIME

We understand that time is of the essence in product development. Our efficient SLA stereolithography workflow allows us to deliver high-quality parts quickly, helping you meet tight deadlines and accelerate your project timelines.

Partnering with Tesseract for your stereolithography 3D printing needs means choosing innovation, precision, and reliability. Our commitment to excellence ensures that every project, big or small, receives the highest level of care and attention. Experience the future of resin 3D printing with Tesseract, where your ideas are transformed into reality with unparalleled detail and accuracy.

FAQ

SLS is an industrial powder bed fusion technology that uses a laser to sinter polymer powder particles layer by layer precisely, creating functional end-use parts and prototypes directly from CAD designs without support structures.

SLS uses various polymer powders including Nylon (PA11, PA12), TPU for flexible parts, and glass-filled materials for enhanced strength, offering excellent mechanical properties for functional applications across industries.

SLS offers no support structures needed, excellent mechanical strength, ability to produce complex geometries, isotropic properties, cost-effective batch production, and parts ready for functional testing or end-use applications immediately after printing.

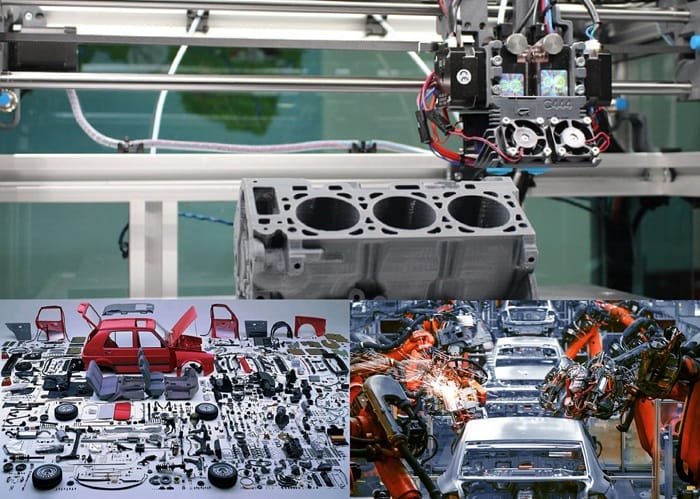

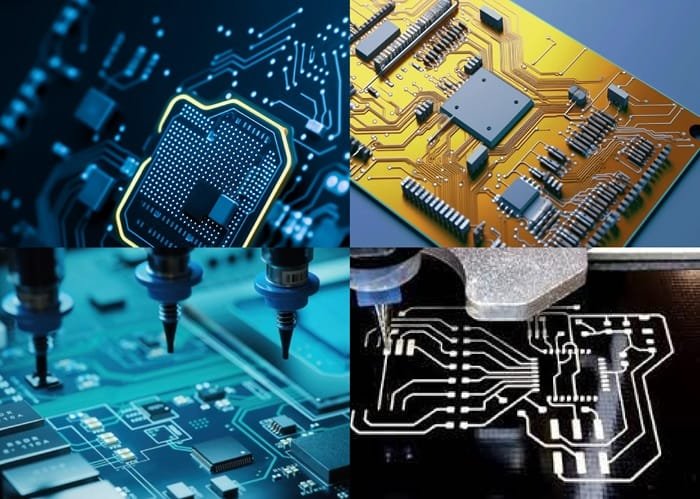

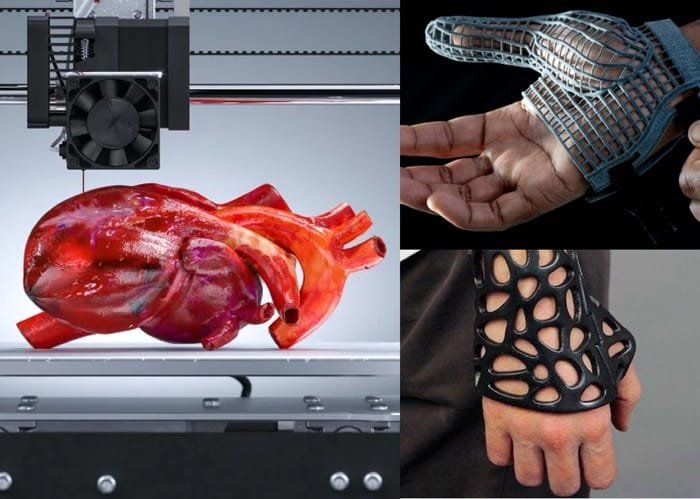

Aerospace, automotive, medical technology, consumer products, electronics, robotics, and industrial manufacturing sectors use SLS for functional prototypes, end-use parts, custom tooling, and low-volume production runs.

Unlike SLA or FDM, SLS doesn’t require support structures as unsintered powder supports the part during printing. This enables complex geometries, nested part production for efficiency, and stronger functional parts with better mechanical properties than most resin-based technologies.