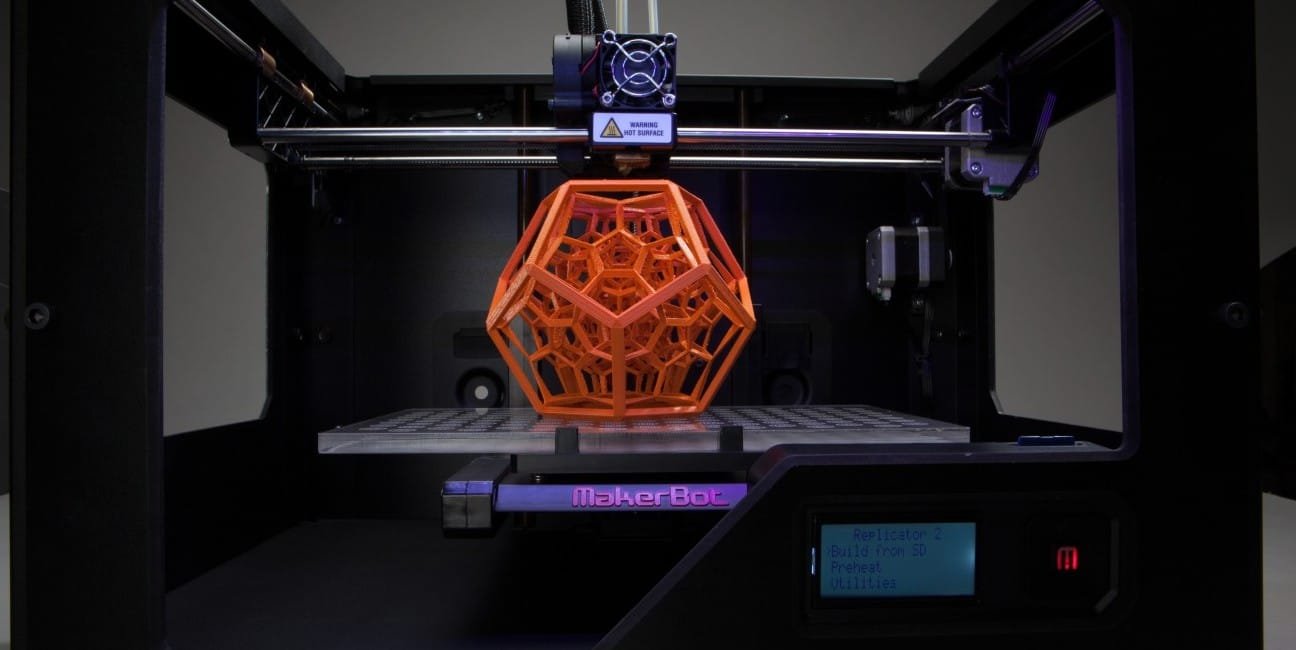

The world of 3D printing and manufacturing is on the cusp of a transformative era. Over the years, additive manufacturing has evolved from a niche technology to a driving force in industries such as healthcare, aerospace, and automotive. As we approach 2025, advancements in design tools, materials, and production methods are set to redefine how businesses innovate and operate.

Sustainability, digital transformation, and cutting-edge applications are shaping the future of this dynamic field. In this blog, we explore the key trends and technologies poised to propel 3D Printing and manufacturing into an exciting new phase of development.

Factors Driving the 3D Printing Revolution in 2025

Sustainability Takes Center Stage

Sustainable practices are shaping the future of 3D printing. By using biodegradable plastics, recycled materials, and waste-reducing techniques, manufacturers are addressing environmental concerns while lowering production costs. This focus aligns with the increasing demand for eco-conscious products.

Artificial Intelligence Transforms Design

AI integration in 3D printing is optimizing workflows and improving design precision. Generative design powered by AI enables innovative, efficient, and lightweight structures. This technology reduces material usage and accelerates prototyping, enhancing productivity across industries.

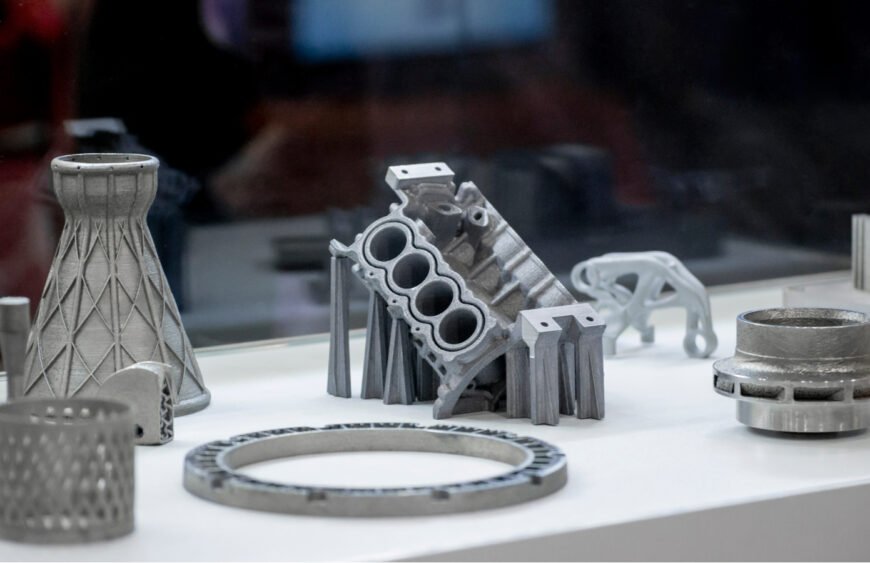

High-Performance Materials Open New Possibilities

Advancements in materials like ceramics, graphene, and bio-inks are broadening the applications of 3D printing. These materials allow for stronger, more flexible, and specialized components, empowering industries like healthcare and aerospace to innovate with precision.

Emerging Trends in Industry Applications

Revolutionizing Healthcare with Bioprinting

3D printing is transforming healthcare by enabling breakthroughs in bioprinting. From custom prosthetics to printed organs and tissues, the technology supports personalized medical solutions. It accelerates research and reduces the cost of creating complex medical devices, paving the way for accessible healthcare innovations.

Driving Innovation in Aerospace and Automotive

In aerospace and automotive industries, 3D printing facilitates the creation of lightweight, high-performance parts. By reducing material wastage and production time, additive manufacturing enhances efficiency while maintaining structural integrity. These advancements enable faster prototyping and more sustainable production.

Customization in Consumer Products

Mass customization is a defining trend in consumer goods, with 3D printing offering unparalleled flexibility. Products like footwear, electronics, and home goods are being tailored to individual preferences at scale. This approach not only improves user satisfaction but also shortens the time-to-market for manufacturers.

Technology Transforming the Manufacturing Ecosystem

Cloud-Based 3D Printing Solutions

Cloud platforms are revolutionizing 3D printing by enabling remote collaboration and streamlined workflows. Designers and manufacturers can now share files, monitor progress, and execute production seamlessly from anywhere. This approach enhances scalability, reduces infrastructure costs, and improves overall efficiency.

IoT Integration for Smarter Production

The Internet of Things (IoT) is empowering 3D printers to become smarter and more connected. Real-time data monitoring, predictive maintenance, and automated quality control are optimizing manufacturing processes. These advancements ensure higher productivity while minimizing downtime and errors.

Edge Computing for Faster Operations

Edge computing is addressing the need for speed and efficiency in 3D printing by processing data locally. Complex algorithms and designs can now be managed at the edge, significantly reducing latency and improving performance. This is particularly beneficial in high-demand or remote production environments.

Overcoming Challenges in 3D Printing

- Bridging the Skills Gap: The lack of skilled professionals hinders the adoption of advanced 3D printing technologies. Specialized training programs, certifications, and workshops are essential to develop expertise and prepare the workforce for evolving industry needs.

- Protecting Intellectual Property (IP): Digital design files are vulnerable to theft, making IP protection a critical challenge. Secure platforms, blockchain solutions, and strong legal frameworks can help safeguard innovation and build trust in the industry.

- Addressing Material Costs and Availability: High costs and limited access to advanced materials restrict adoption. Promoting affordable alternatives and local material production can lower costs and improve accessibility for manufacturers.

Future Trends and Opportunities for 3D Printing

Expanding Applications Across Industries

3D printing is breaking barriers in diverse sectors such as construction, fashion, and renewable energy. From printing sustainable building components to creating customized wearable technology, the potential for new applications is vast. Industries can leverage these innovations to enhance efficiency and deliver personalized products.

Investment in Research and Development

Ongoing R&D is essential to push the boundaries of 3D printing technologies. Enhanced materials, faster printing techniques, and automated workflows will drive adoption further. Collaboration between private enterprises and research institutions can accelerate innovation and improve accessibility.

Preparing for a Digitally-Driven Future

Digital transformation will play a pivotal role in the future of 3D printing. Integration with AI, IoT, and cloud computing will enable smarter, more connected manufacturing systems. Businesses must adopt advanced technologies and prioritize adaptability to remain competitive in this rapidly evolving landscape.

Conclusion

The year 2025 marks an exciting phase in the evolution of 3D printing and manufacturing. From sustainable practices and advanced materials to AI-driven innovation and IoT integration, the technology is redefining industries and opening doors to endless possibilities. Overcoming challenges like skills gaps, IP protection, and material costs will be critical for harnessing its full potential. By embracing these trends and investing in innovation, businesses can not only stay ahead but also lead the transformation of global manufacturing. The future of 3D printing is limitless—those who adapt will thrive in this dynamic new era.