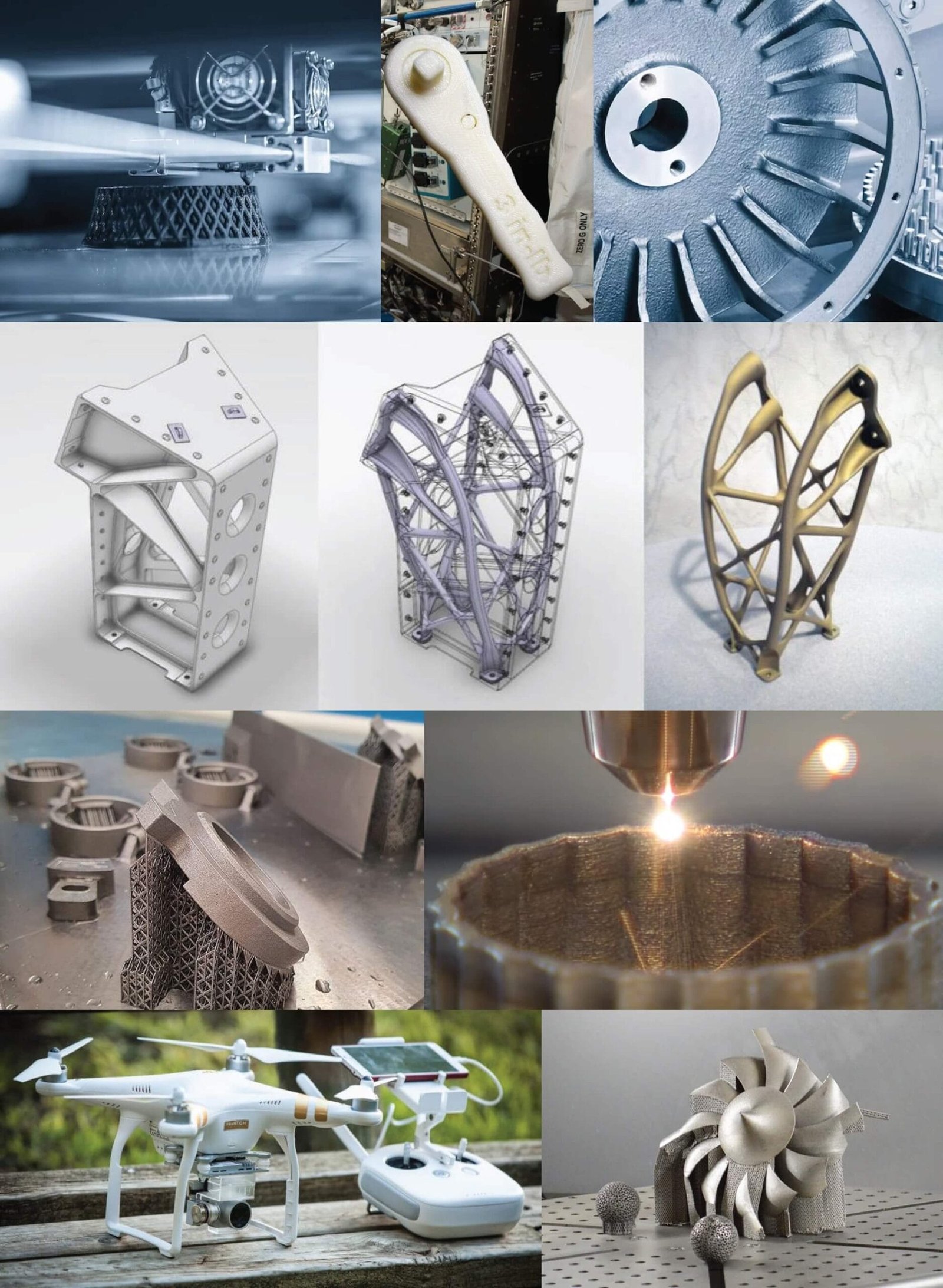

Aerospace

Aerospace Innovations through Additive Manufacturing

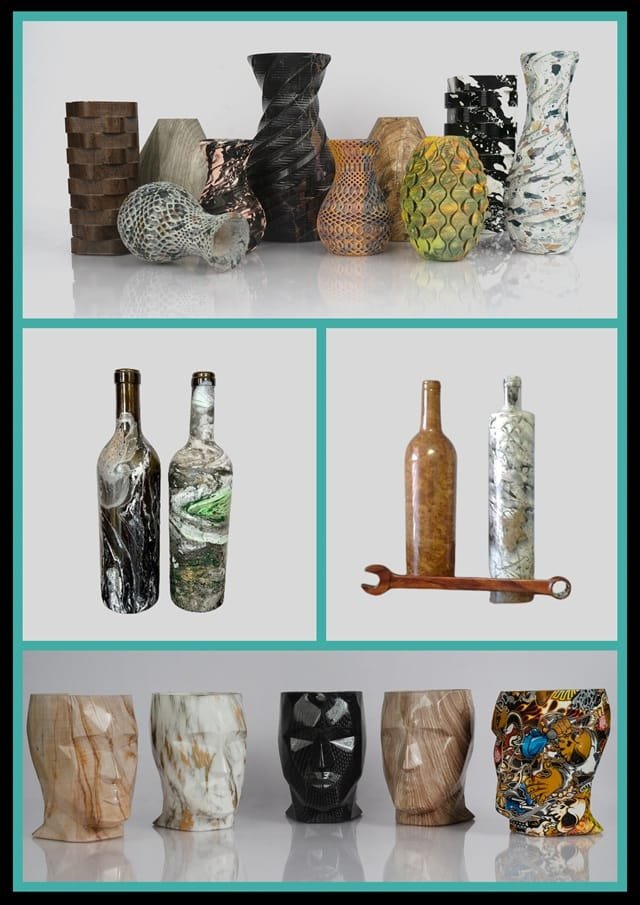

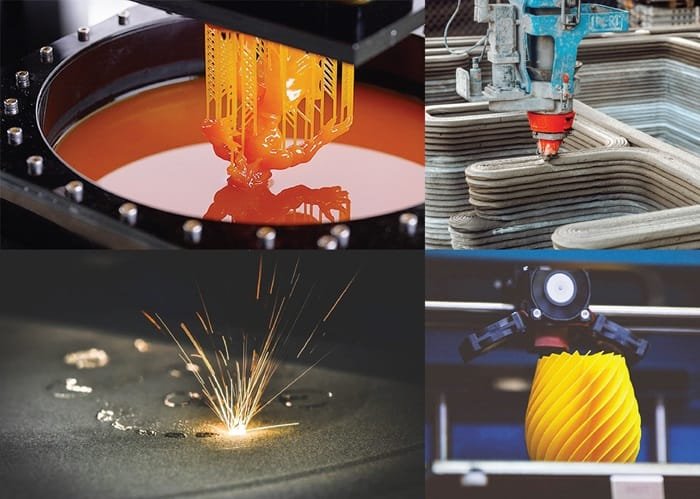

Additive Manufacturing, commonly known as 3D Printing, offers a clear value proposition to the aerospace industry by enabling the fabrication of structurally intricate designs. It helps achieve non-traditional, organic shapes that provide high mechanical performance while minimising the weight. The early adoption and ongoing contributions of 3D printing technologies and materials are revolutionising aerospace manufacturing.

Applications

- Manufacturing Productivity & Fuel Efficiency: Leveraging global 3D Printing solutions to reduce fuel costs through lightweighting and parts consolidation, ultimately enhancing manufacturing productivity.

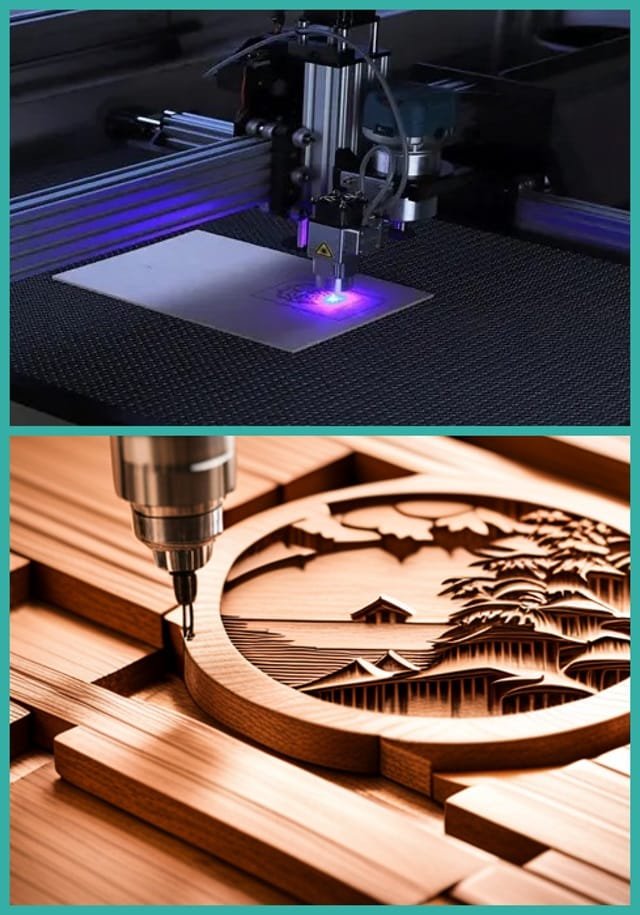

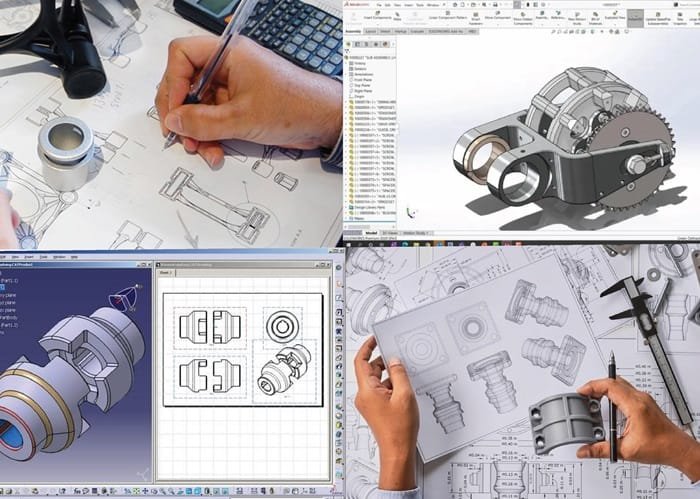

- Innovative Prototyping & Casting Patterns: Utilising 3D Printing for rapid concept models and innovative casting patterns, facilitating faster design concepts, validation testing, and a shorter product development cycle.

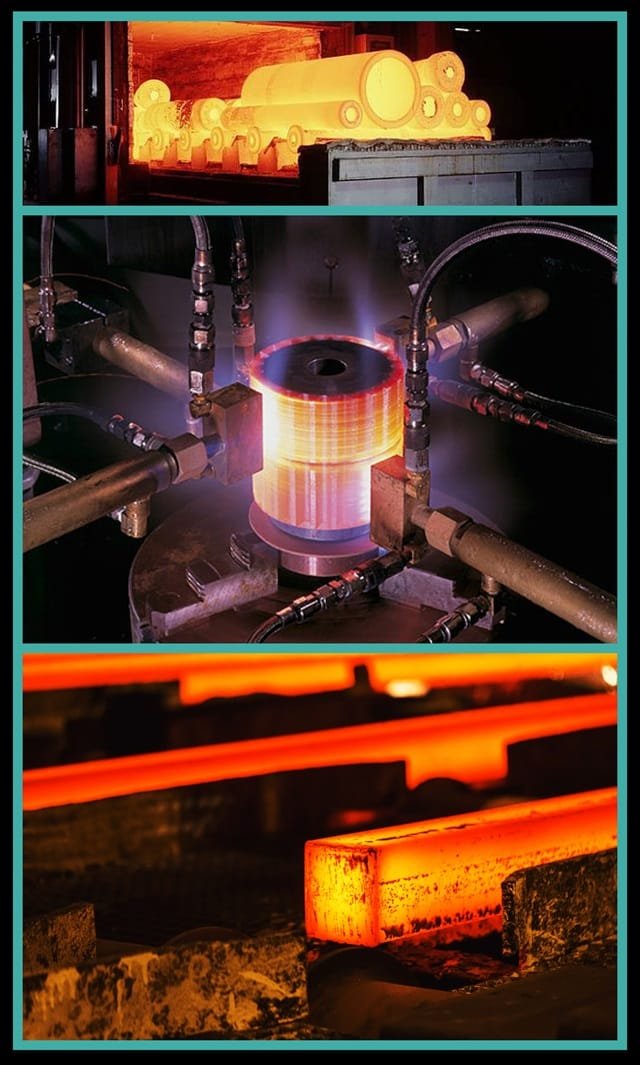

- Direct Metal Printing for Airworthy Parts: Employing cutting-edge technologies like Direct Metal Printing (DMP) for producing airworthy parts with precision and efficiency.

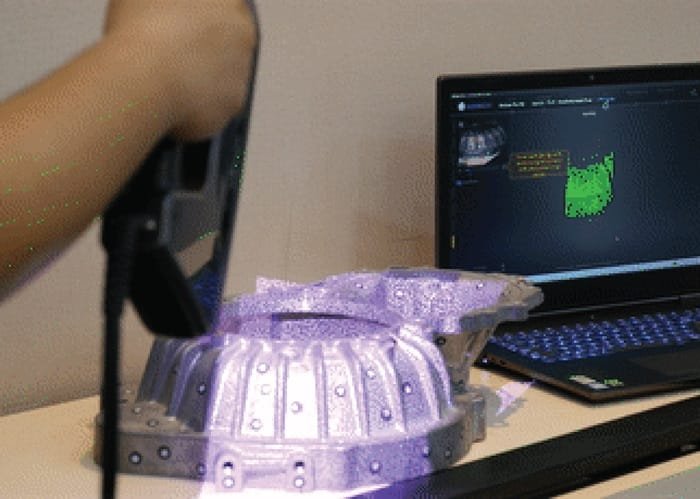

- Equipment Repair & Functional Restoration: Utilising technologies like Wire Arc Additive Manufacturing (WAAM) and 3D Scanning to repair and restore worn-out surfaces of military equipment, ensuring longevity and functionality.

- 3D Data Recovery and Replication: Utilising 3D scanning techniques to reverse engineer and replicate available parts, ensuring swift replacement in case of stock shortages.

- Optimising Drone Design: Leveraging 3D Printing for manufacturing drones and iterating on designs to achieve low weight and high functionality.